In today’s competitive business landscape, small businesses face the challenge of managing their inventory efficiently. Small business inventory programs offer a solution, providing a range of tools and techniques to help businesses streamline their inventory management processes, reduce costs, and improve customer satisfaction.

This comprehensive guide will delve into the intricacies of small business inventory programs, exploring the benefits, techniques, software options, and best practices to help businesses optimize their inventory management strategies.

Inventory Management Techniques

Inventory management is crucial for small businesses to optimize stock levels, reduce costs, and improve efficiency. Effective inventory management techniques provide businesses with greater control over their inventory, enabling them to make informed decisions about stock replenishment and minimize the risk of overstocking or stockouts.

Inventory management techniques involve various strategies and practices that help businesses track, organize, and manage their inventory efficiently. These techniques can be manual or automated, depending on the size and complexity of the business. Implementing these techniques can result in significant benefits, including reduced inventory costs, improved customer service, and increased profitability.

Just-in-Time (JIT) Inventory

- JIT inventory is a technique that aims to minimize inventory levels by only ordering and receiving inventory when it is needed for production or sale.

- This technique helps reduce storage costs, minimize waste, and improve cash flow by reducing the amount of inventory held at any given time.

Economic Order Quantity (EOQ)

- EOQ is a formula used to determine the optimal quantity of inventory to order at a time.

- It considers factors such as demand, ordering costs, and holding costs to calculate the most cost-effective order quantity.

First-In, First-Out (FIFO)

- FIFO is an inventory valuation method that assumes that the oldest inventory is sold first.

- This method helps ensure that inventory is not outdated and reduces the risk of spoilage or obsolescence.

Last-In, First-Out (LIFO)

- LIFO is an inventory valuation method that assumes that the most recently acquired inventory is sold first.

- This method can be advantageous in periods of rising prices, as it results in lower cost of goods sold and higher reported profits.

Inventory Optimization

Inventory optimization is a key aspect of inventory management that involves analyzing and adjusting inventory levels to meet demand while minimizing costs.

Inventory optimization techniques include:

- Safety stock:Maintaining a buffer stock to prevent stockouts during unexpected fluctuations in demand or supply.

- Reorder point:Setting a trigger level for reordering inventory to avoid stockouts while minimizing overstocking.

- Lead time:Considering the time it takes to receive new inventory when calculating reorder points and safety stock levels.

By implementing effective inventory management techniques and optimizing inventory levels, small businesses can improve their operational efficiency, reduce costs, and enhance customer satisfaction.

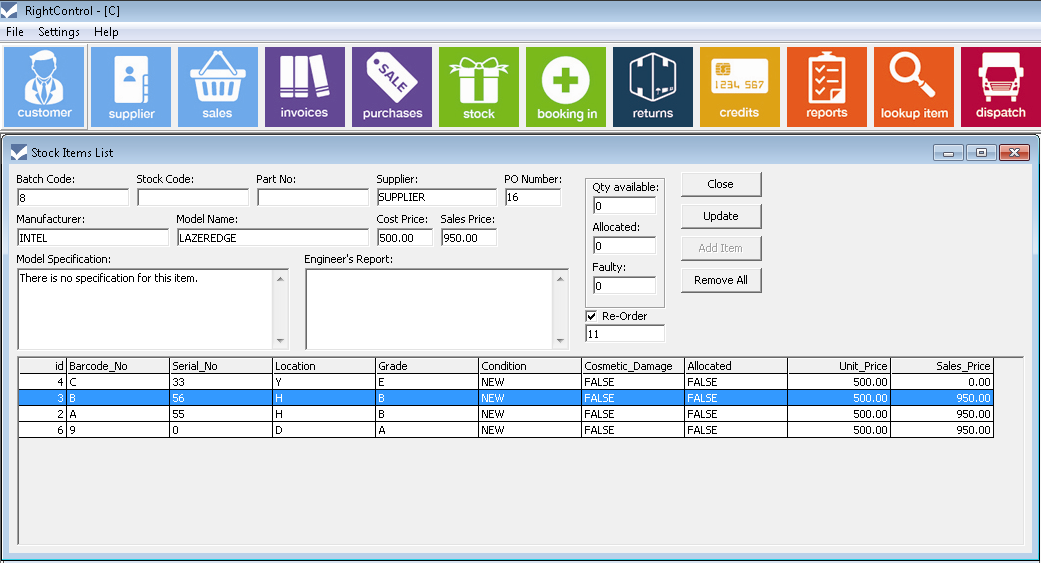

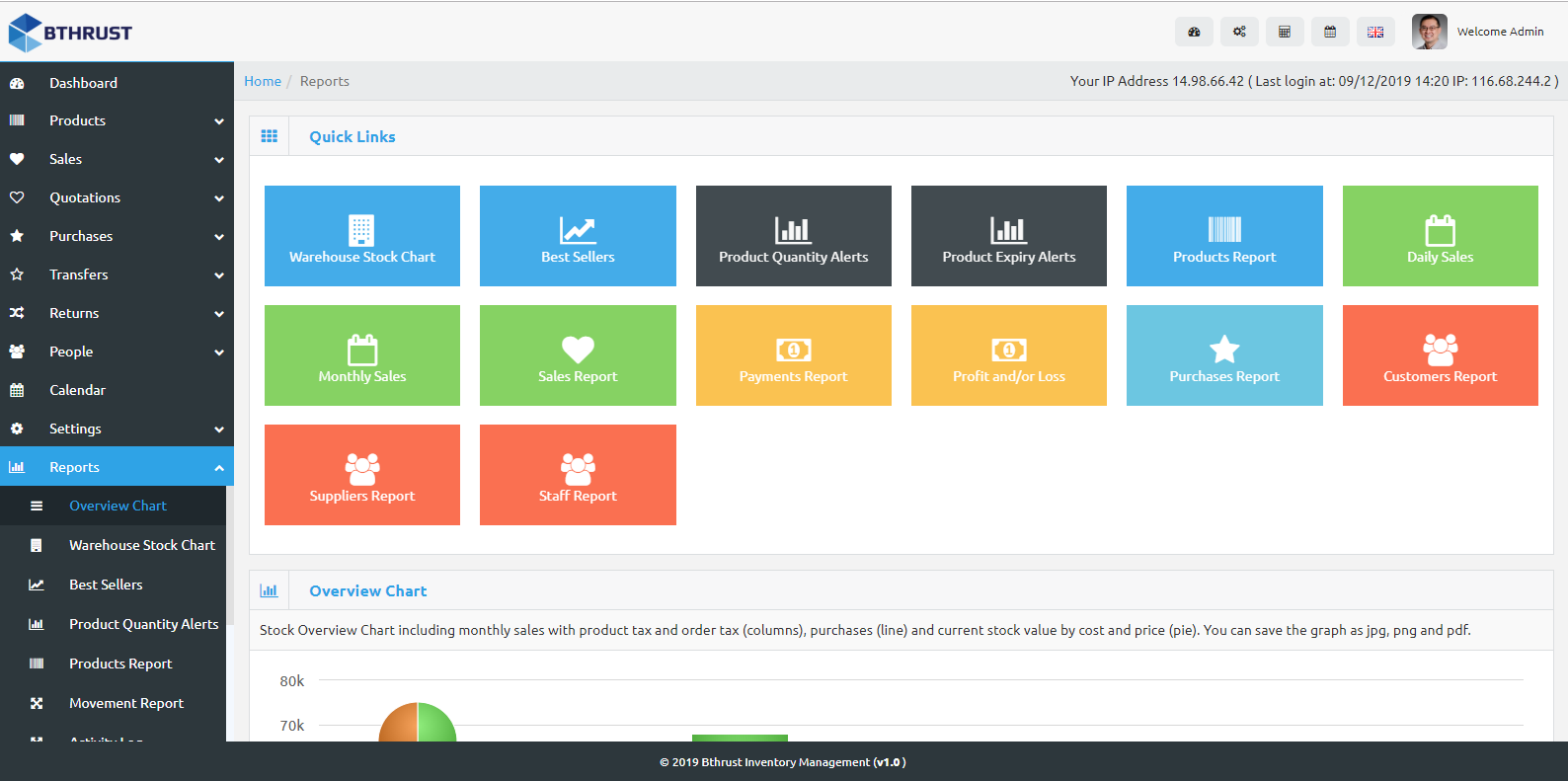

Inventory Management Software

Inventory management software is a valuable tool for small businesses, as it can help them track inventory levels, manage orders, and automate many of the tasks associated with inventory management. This can free up time and resources that can be used to focus on other aspects of the business.

There are many different inventory management software options available, so it’s important to choose one that is right for your business. Some of the factors to consider when choosing inventory management software include:

- The size of your business

- The types of products you sell

- Your budget

- Your technical expertise

Benefits of Using Inventory Management Software

There are many benefits to using inventory management software, including:

- Improved accuracy:Inventory management software can help you track inventory levels more accurately, which can reduce the risk of overstocking or understocking.

- Reduced costs:Inventory management software can help you reduce costs by optimizing inventory levels and automating tasks.

- Improved customer service:Inventory management software can help you improve customer service by ensuring that you always have the products that your customers want in stock.

- Increased sales:Inventory management software can help you increase sales by making it easier to track customer demand and adjust inventory levels accordingly.

Choosing the Right Inventory Management Software

When choosing inventory management software, it’s important to consider the following factors:

- The size of your business:If you have a small business, you may not need a lot of features in your inventory management software. However, if you have a larger business, you may need software that can handle a larger volume of transactions and products.

- The types of products you sell:If you sell products that are perishable or have a short shelf life, you may need inventory management software that can track expiration dates and help you manage inventory turnover.

- Your budget:Inventory management software can range in price from free to thousands of dollars per month. It’s important to set a budget before you start shopping for software.

- Your technical expertise:If you’re not comfortable with technology, you may want to choose inventory management software that is easy to use and has a good support team.

Once you’ve considered these factors, you can start shopping for inventory management software. There are many different software options available, so it’s important to compare the features and prices of different products before you make a decision.

Comparison of Inventory Management Software Options

The following table compares some of the most popular inventory management software options for small businesses:

| Software | Features | Price |

|---|---|---|

| QuickBooks | – Inventory tracking

|

$10 per month |

| Shopify | – Inventory tracking

|

$29 per month |

| Zoho Inventory | – Inventory tracking

|

$19 per month |

| NetSuite | – Inventory tracking

|

$999 per month |

Inventory Tracking

Inventory tracking is the process of monitoring the quantity and location of inventory items. It is an essential part of inventory management, as it allows businesses to keep track of their stock levels and avoid stockouts. There are a number of different methods for tracking inventory, including manual tracking, automated tracking, and RFID tracking.

Manual tracking is the simplest method of inventory tracking. It involves manually counting and recording the quantity of each inventory item on a regular basis. This method is relatively inexpensive, but it can be time-consuming and error-prone.

Automated tracking uses technology to track inventory levels. This can be done using a variety of methods, such as barcode scanners, RFID tags, and inventory management software. Automated tracking is more accurate and efficient than manual tracking, but it can be more expensive.

RFID tracking is a type of automated tracking that uses RFID tags to track inventory items. RFID tags are small, wireless devices that can be attached to inventory items. When an RFID tag is scanned, it transmits its unique ID number to a reader.

This information can then be used to track the location and quantity of inventory items.

Step-by-Step Guide to Implementing an Inventory Tracking System

- Identify the inventory items that you need to track.

- Choose a method for tracking inventory.

- Implement the inventory tracking system.

- Train your staff on how to use the inventory tracking system.

- Monitor the inventory tracking system and make adjustments as needed.

Benefits of Using Barcodes and RFID Tags for Inventory Tracking

- Improved accuracy

- Reduced labor costs

- Increased efficiency

- Better customer service

Inventory Control

Inventory control is a crucial aspect of inventory management, ensuring optimal stock levels, minimizing waste, and maintaining efficient operations. It involves establishing and implementing policies and procedures to effectively manage inventory throughout its lifecycle.Inventory control aims to balance the need for sufficient stock to meet customer demand while avoiding excessive inventory levels that can lead to storage costs, spoilage, and obsolescence.

Effective inventory control systems help businesses optimize inventory levels, reduce costs, improve customer service, and enhance overall operational efficiency.

Best Practices for Inventory Control

Implementing robust inventory control practices is essential for effective inventory management. Some best practices include:

- Establish clear inventory policies and procedures, outlining roles, responsibilities, and processes.

- Implement an accurate inventory tracking system, utilizing technology to automate processes and ensure data integrity.

- Conduct regular inventory audits to verify physical inventory against records, identifying discrepancies and preventing errors.

- Use inventory optimization techniques, such as ABC analysis and safety stock calculations, to determine optimal inventory levels.

- Establish a perpetual inventory system, providing real-time visibility into inventory levels and facilitating timely replenishment.

Importance of Cycle Counting

Cycle counting is a crucial inventory control technique that involves physically counting inventory on a regular basis, typically on a rotating schedule. It helps identify and correct errors in inventory records, ensuring accuracy and preventing discrepancies. Cycle counting also provides valuable insights into inventory movement patterns, helping businesses optimize inventory levels and reduce shrinkage.

Inventory Forecasting

Inventory forecasting is the process of predicting future inventory levels based on historical data and current trends. It helps businesses determine the optimal amount of inventory to hold to meet customer demand while minimizing costs.

Inventory forecasting techniques include:

- Time series analysis: This method uses historical data to identify patterns and trends in inventory levels.

- Causal forecasting: This method considers external factors, such as economic conditions and competitor actions, that can influence inventory demand.

- Demand forecasting: This method predicts future demand based on historical sales data, market research, and other factors.

Inventory Forecasting Models

Common inventory forecasting models include:

- Exponential smoothing: This model assumes that future inventory levels will be similar to recent levels, with some adjustments for trends and seasonality.

- Moving average: This model calculates the average inventory level over a specified period, which can be used to smooth out fluctuations in demand.

- Regression analysis: This model uses statistical techniques to identify the relationship between inventory levels and other factors, such as sales or economic indicators.

Factors to Consider

When forecasting inventory, businesses should consider factors such as:

- Historical demand: This provides a baseline for forecasting future demand.

- Seasonality: Inventory demand can vary significantly depending on the time of year.

- Lead time: This is the time it takes to receive inventory from suppliers.

- Safety stock: This is an additional amount of inventory held to buffer against unexpected fluctuations in demand.

- Customer service levels: Businesses must balance inventory levels with customer service goals.

Inventory Replenishment

Inventory replenishment refers to the process of restocking inventory to meet customer demand and maintain optimal inventory levels. Different inventory replenishment strategies exist, each with its own advantages and disadvantages.

The choice of inventory replenishment strategy depends on factors such as product demand, lead time, and inventory holding costs. Here are some common inventory replenishment strategies:

Periodic Review System

- Inventory levels are reviewed at regular intervals, such as weekly or monthly.

- Orders are placed to bring inventory levels up to a predetermined target level.

- Suitable for products with stable demand and long lead times.

Continuous Review System

- Inventory levels are monitored continuously.

- Orders are placed when inventory levels reach a predefined reorder point.

- Suitable for products with fluctuating demand and short lead times.

Just-in-Time (JIT) System

- Inventory is ordered and received just before it is needed for production or sale.

- Reduces inventory holding costs and improves inventory turnover.

- Suitable for products with high demand and short lead times.

| Strategy | Pros | Cons |

|---|---|---|

| Periodic Review | – Lower ordering costs

|

– Potential for stockouts

|

| Continuous Review | – Reduced risk of stockouts

|

– Higher ordering costs

|

| Just-in-Time | – Minimal inventory holding costs

|

– Requires accurate demand forecasting

|

Calculating Optimal Inventory Replenishment Quantity

The optimal inventory replenishment quantity (EOQ) is the quantity that minimizes total inventory costs, including ordering costs and inventory holding costs. The EOQ can be calculated using the following formula:

EOQ = √(2*D*O)/H

where:

- D = annual demand for the product

- O = ordering cost per order

- H = inventory holding cost per unit per year

Inventory Valuation

Inventory valuation is the process of determining the value of a company’s inventory. This is important for several reasons, including:

- Financial reporting: Inventory is a major asset for many companies, and its value must be accurately reported on the balance sheet.

- Taxation: The value of inventory can affect a company’s tax liability.

- Decision-making: Accurate inventory valuation is essential for making informed decisions about purchasing, production, and sales.

There are several different methods of inventory valuation. The most common methods are:

- First-in, first-out (FIFO): This method assumes that the oldest inventory is sold first. As a result, the cost of goods sold is based on the cost of the oldest inventory on hand.

- Last-in, first-out (LIFO): This method assumes that the newest inventory is sold first. As a result, the cost of goods sold is based on the cost of the newest inventory on hand.

- Weighted average cost: This method calculates the average cost of all inventory on hand. The average cost is then used to determine the cost of goods sold.

The choice of which inventory valuation method to use depends on a number of factors, including the nature of the business, the type of inventory, and the company’s accounting policies.

Calculating Inventory Value

The following formula can be used to calculate the value of inventory:

Inventory Value = Quantity on Hand

Unit Cost

The quantity on hand is the number of units of inventory on hand. The unit cost is the cost of each unit of inventory.

Importance of Accurate Inventory Valuation

Accurate inventory valuation is essential for a number of reasons. These reasons include:

- Financial reporting: Inventory is a major asset for many companies, and its value must be accurately reported on the balance sheet. Inaccurate inventory valuation can lead to financial misstatements, which can have a negative impact on the company’s reputation and financial performance.

- Taxation: The value of inventory can affect a company’s tax liability. Inaccurate inventory valuation can lead to overpaying or underpaying taxes, which can have a negative impact on the company’s profitability.

- Decision-making: Accurate inventory valuation is essential for making informed decisions about purchasing, production, and sales. Inaccurate inventory valuation can lead to poor decision-making, which can have a negative impact on the company’s profitability.

Inventory Reporting

Inventory reporting is essential for small businesses to track and manage their inventory effectively. It provides valuable insights into the status of inventory, helps identify trends, and supports decision-making.

Small businesses should use the following key inventory reports:

- Inventory Summary Report:Provides an overview of the total inventory, including the quantity and value of each item.

- Inventory Turnover Report:Shows how quickly inventory is being sold and replaced, indicating the efficiency of inventory management.

- Inventory Aging Report:Identifies items that have been in stock for an extended period, helping businesses prioritize sales and reduce the risk of obsolescence.

- Inventory Valuation Report:Estimates the total value of the inventory based on different valuation methods, such as FIFO (First-In, First-Out) or LIFO (Last-In, First-Out).

Sample Inventory Report Template

The following table provides a sample inventory report template:

| Item | Quantity | Unit Cost | Total Value |

|---|---|---|---|

| Product A | 100 | $10 | $1,000 |

| Product B | 50 | $15 | $750 |

| Product C | 25 | $20 | $500 |

| Total | 175 | $2,250 |

Interpreting Inventory Reports

To interpret inventory reports effectively, businesses should consider the following:

- Identify trends:Track changes in inventory levels and turnover rates over time to identify patterns and make informed decisions.

- Analyze aging inventory:Determine which items are moving slowly and consider implementing strategies to sell them or reduce their purchase.

- Monitor inventory valuation:Ensure that the inventory valuation method aligns with the business’s accounting practices and provides accurate financial reporting.

Inventory Management for Different Industries: Small Business Inventory Programs

Inventory management strategies vary across industries due to unique challenges and requirements. Understanding these differences enables businesses to optimize their inventory practices.

Retail Industry, Small business inventory programs

Retailers face challenges with high inventory turnover, seasonality, and customer demand fluctuations. Effective inventory management includes:

- Demand forecasting using historical data and market trends.

- Maintaining optimal stock levels to avoid overstocking and stockouts.

- Implementing point-of-sale (POS) systems for real-time inventory tracking.

Manufacturing Industry

Manufacturers deal with raw materials, work-in-progress (WIP), and finished goods inventory. Challenges include production planning, supply chain management, and quality control. Effective inventory management practices include:

- Material requirements planning (MRP) to ensure timely availability of materials.

- Just-in-time (JIT) inventory systems to minimize inventory holding costs.

- Quality control measures to prevent defective products from entering the inventory.

Healthcare Industry

Healthcare providers manage inventory of medical supplies, pharmaceuticals, and equipment. Challenges include maintaining adequate stock levels for patient care, managing expiration dates, and ensuring compliance with regulations. Effective inventory management practices include:

- Par level inventory systems to set minimum and maximum stock levels.

- First-in, first-out (FIFO) inventory method to ensure proper stock rotation.

- Inventory tracking systems to monitor stock levels and expiration dates.

Inventory Management Trends

The realm of inventory management is constantly evolving, driven by technological advancements and changing business dynamics. Staying abreast of these trends is crucial for small businesses to optimize their inventory operations, reduce costs, and gain a competitive edge.

Several notable trends are shaping the future of inventory management:

Cloud-Based Inventory Management

Cloud-based inventory management systems are gaining popularity among small businesses. These systems offer several advantages, including:

- Real-time inventory visibility across multiple locations

- Automated inventory tracking and replenishment

- Reduced IT costs and maintenance

Data Analytics and AI

Data analytics and artificial intelligence (AI) are transforming inventory management. Businesses can now leverage data to:

- Forecast demand more accurately

- Identify slow-moving and obsolete inventory

- Optimize inventory levels to minimize holding costs

Mobile Inventory Management

Mobile inventory management apps allow businesses to manage inventory on the go. These apps provide:

- Real-time inventory updates

- Barcode scanning for quick and accurate inventory tracking

- Improved warehouse efficiency

RFID and IoT

Radio frequency identification (RFID) and the Internet of Things (IoT) are enabling businesses to track inventory items with greater precision. This technology allows for:

- Automated inventory counting

- Improved inventory accuracy

- Real-time tracking of inventory movement

Sustainability in Inventory Management

Businesses are increasingly prioritizing sustainability in their inventory management practices. This includes:

- Reducing waste and excess inventory

- Using eco-friendly packaging materials

- Optimizing inventory levels to minimize environmental impact

Recommendations for Staying Ahead

To stay ahead of the curve in inventory management, small businesses should:

- Embrace cloud-based inventory management systems

- Leverage data analytics and AI to optimize inventory operations

- Implement mobile inventory management apps

- Explore RFID and IoT technologies for improved inventory tracking

- Prioritize sustainability in inventory management practices

Closure

By embracing the power of small business inventory programs, businesses can gain a competitive edge, improve their operational efficiency, and ultimately drive growth. With the right tools and strategies in place, small businesses can effectively manage their inventory, reduce waste, and enhance customer satisfaction, setting themselves up for long-term success in the ever-evolving business environment.

Detailed FAQs

What are the benefits of using small business inventory programs?

Small business inventory programs offer numerous benefits, including improved inventory accuracy, reduced costs, enhanced customer satisfaction, and increased operational efficiency.

How do I choose the right inventory management software for my small business?

Consider factors such as the size of your business, the type of inventory you manage, your budget, and the features and integrations you need.

What are some best practices for inventory control?

Establish clear inventory policies, implement cycle counting, and use technology to automate inventory tracking and replenishment.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY