Embark on a journey into the realm of Praxair Surface Technologies, a global leader in surface treatment solutions that empower industries to achieve卓越. With a rich history and unwavering commitment to innovation, Praxair Surface Technologies has established itself as a trusted partner for businesses seeking to enhance the performance, durability, and sustainability of their products.

Delving deeper into the company’s core technologies, we uncover a suite of advanced processes, including thermal spray, HVOF, and cold spray. These cutting-edge techniques enable Praxair Surface Technologies to provide tailored solutions for a diverse range of industries, including aerospace, automotive, energy, and manufacturing.

Company Overview

Praxair Surface Technologies is a leading global provider of surface treatment technologies and services. The company was founded in 1939 and is headquartered in Indianapolis, Indiana, USA. Praxair Surface Technologies has a global presence with operations in over 30 countries and serves a wide range of industries, including aerospace, automotive, energy, and medical.

Praxair Surface Technologies’ mission is to provide innovative surface treatment solutions that improve the performance and durability of our customers’ products. The company’s vision is to be the global leader in surface treatment technologies and services.

Global Presence

Praxair Surface Technologies has a global presence with operations in over 30 countries. The company has manufacturing facilities in North America, Europe, and Asia. Praxair Surface Technologies also has a network of sales and service offices around the world.

Industry Leadership

Praxair Surface Technologies is a leader in the surface treatment industry. The company has a long history of innovation and has developed a number of patented surface treatment technologies. Praxair Surface Technologies is also a member of several industry organizations, including the American Society for Metals (ASM) and the Society of Vacuum Coaters (SVC).

Core Technologies

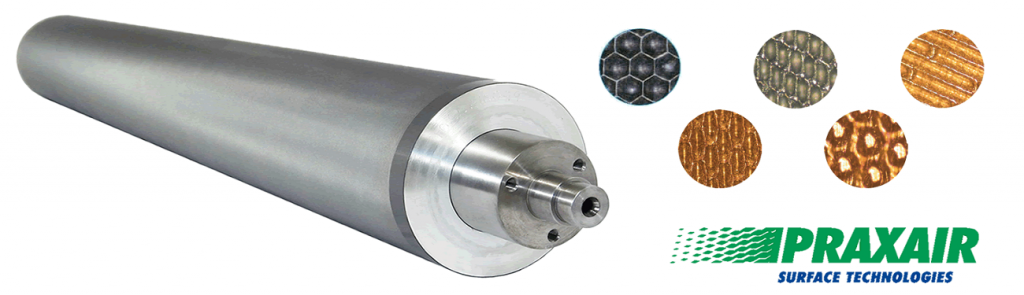

Praxair Surface Technologies is a global leader in thermal spray, HVOF, and cold spray technologies, providing advanced solutions for various industries.

Thermal spray is a process where a molten or semi-molten material is sprayed onto a substrate, creating a protective or functional coating. High-velocity oxygen fuel (HVOF) is a variant of thermal spray that utilizes a high-velocity flame to propel the coating material, resulting in dense and wear-resistant coatings.

Cold Spray

Cold spray is a unique process that utilizes a supersonic jet of inert gas to propel powdered materials onto a substrate at high velocities. Unlike thermal spray, cold spray does not involve melting the coating material, preserving its properties and microstructure.

Cold spray technology offers several advantages, including:

- Low-temperature process, minimizing substrate distortion and preserving material properties.

- High deposition rates, allowing for rapid coating application.

- Ability to deposit a wide range of materials, including metals, ceramics, and composites.

- Excellent coating adhesion and wear resistance.

Cold spray is widely used in industries such as aerospace, automotive, energy, and manufacturing for applications such as corrosion protection, wear resistance, and repair.

Product Offerings

Praxair Surface Technologies offers a comprehensive range of products designed to enhance the performance and longevity of various surfaces. Their product portfolio encompasses advanced thermal spray systems, HVOF systems, cold spray systems, and a diverse range of coating materials.

Each product category is meticulously engineered to cater to specific industry requirements and deliver exceptional results.

Thermal Spray Systems

- High-quality thermal spray systems that utilize various coating technologies, including plasma spray, flame spray, and wire arc spray.

- Designed for precision application of coatings, ensuring optimal performance and durability.

HVOF Systems

- Advanced high-velocity oxygen-fuel (HVOF) systems engineered for demanding applications.

- Deliver high-density, wear-resistant coatings with superior adhesion and longevity.

Cold Spray Systems

- Innovative cold spray systems that utilize supersonic gas flow to deposit coatings without the need for high temperatures.

- Produce coatings with exceptional wear resistance, corrosion resistance, and thermal insulation properties.

Coating Materials

- Extensive selection of coating materials, including ceramics, metals, and polymers.

- Custom-tailored to meet specific performance requirements, such as wear resistance, corrosion resistance, and thermal protection.

Industries Served

Praxair Surface Technologies serves a wide range of industries, providing customized surface treatment solutions tailored to meet specific needs.

The company’s core technologies enable it to offer a comprehensive suite of surface treatment services, including thermal spray coatings, plasma nitriding, and physical vapor deposition (PVD), among others.

Aerospace

Praxair Surface Technologies plays a crucial role in the aerospace industry, providing advanced surface treatment solutions that enhance the performance, durability, and safety of aircraft components.

- Thermal spray coatings protect against wear, corrosion, and oxidation, extending the lifespan of critical parts.

- Plasma nitriding improves fatigue strength and wear resistance, enhancing the reliability of landing gear and other high-stress components.

Automotive

Praxair Surface Technologies supports the automotive industry by providing surface treatment solutions that improve engine efficiency, reduce emissions, and enhance the durability of vehicle components.

- Thermal spray coatings on pistons and cylinder heads reduce friction and wear, leading to improved fuel efficiency and reduced emissions.

- Plasma nitriding on transmission gears and bearings enhances wear resistance and fatigue strength, extending component life and reducing maintenance costs.

Energy

Praxair Surface Technologies provides surface treatment solutions for the energy industry, helping to improve the efficiency, reliability, and lifespan of critical components.

- Thermal spray coatings on gas turbine blades protect against corrosion and erosion, extending the life of these expensive components.

- Plasma nitriding on oil and gas drilling tools enhances wear resistance and corrosion resistance, reducing downtime and maintenance costs.

Medical

Praxair Surface Technologies offers surface treatment solutions for the medical industry, improving the biocompatibility, wear resistance, and longevity of medical devices and implants.

- Thermal spray coatings on orthopedic implants provide a biocompatible surface that promotes bone growth and reduces the risk of infection.

- Plasma nitriding on surgical instruments enhances wear resistance and corrosion resistance, extending the lifespan of these critical tools.

Customer Success Stories

Praxair Surface Technologies has a proven track record of delivering exceptional results for its customers across various industries. Our innovative solutions have helped companies improve productivity, reduce costs, and enhance product performance.

Here are a few examples of how Praxair Surface Technologies has made a positive impact on our customers’ businesses:

Case Study: Aerospace Manufacturer

A leading aerospace manufacturer was facing challenges with the durability of its aircraft components. Praxair Surface Technologies provided a customized thermal spray coating solution that significantly extended the lifespan of the components, reducing maintenance costs and improving aircraft reliability.

Testimonial: Automotive Supplier

“Praxair Surface Technologies’ laser cladding technology has revolutionized our production process. It has enabled us to produce higher-quality components with improved wear resistance and corrosion resistance. As a result, we have seen a significant increase in customer satisfaction and a reduction in warranty claims.”

Case Study: Medical Device Manufacturer, Praxair surface technologies

A medical device manufacturer was struggling to meet the strict regulatory requirements for biocompatibility and surface finish. Praxair Surface Technologies developed a proprietary coating process that met all the necessary specifications, ensuring the safety and performance of the medical devices.

Research and Development

Praxair Surface Technologies is committed to innovation and research, investing heavily in developing new technologies and improving existing ones. The company’s R&D efforts are focused on creating innovative solutions that address the evolving needs of its customers.

Praxair Surface Technologies has a dedicated team of scientists and engineers who are constantly exploring new ideas and developing new technologies. The company’s R&D efforts are focused on a variety of areas, including:

New Technologies

- Developing new surface treatment technologies that improve the performance and durability of materials.

- Creating new coatings and materials that are resistant to wear, corrosion, and other environmental factors.

- Developing new processes that are more efficient and environmentally friendly.

Improving Existing Technologies

- Improving the performance of existing surface treatment technologies.

- Reducing the cost of existing surface treatment technologies.

- Making existing surface treatment technologies more environmentally friendly.

Praxair Surface Technologies’ commitment to R&D has resulted in the development of a number of innovative new technologies, including:

- A new plasma spray coating process that produces coatings with improved wear resistance and corrosion resistance.

- A new thermal spray coating process that produces coatings with improved adhesion and toughness.

- A new laser cladding process that produces coatings with improved wear resistance and corrosion resistance.

Praxair Surface Technologies’ R&D efforts are essential to the company’s continued success. By investing in new technologies and improving existing ones, Praxair Surface Technologies is able to provide its customers with the best possible surface treatment solutions.

Sustainability

Praxair Surface Technologies is committed to environmental protection and sustainability throughout its operations. The company’s processes and products are designed to minimize environmental impact and promote responsible manufacturing practices.

Praxair Surface Technologies has implemented several initiatives to reduce its environmental footprint, including:

Energy Efficiency

- Upgrading to energy-efficient equipment and processes

- Utilizing renewable energy sources

- Implementing energy management systems

Waste Reduction

- Minimizing waste generation through process optimization

- Recycling and reusing materials

- Collaborating with suppliers to reduce packaging and waste

Environmental Compliance

- Adhering to all applicable environmental regulations

- Conducting regular environmental audits

- Investing in pollution control technologies

Praxair Surface Technologies’ sustainability efforts have resulted in significant environmental benefits, including:

Reduced Greenhouse Gas Emissions

- Lowering energy consumption

- Switching to renewable energy sources

- Improving process efficiency

Diminished Water Usage

- Implementing water-saving technologies

- Recycling and reusing water

- Reducing water consumption in manufacturing processes

Minimized Waste Generation

- Optimizing processes to reduce waste

- Recycling and reusing materials

- Collaborating with suppliers to reduce packaging and waste

Praxair Surface Technologies is dedicated to continuous improvement in its sustainability practices. The company is committed to minimizing its environmental impact while providing innovative and environmentally friendly solutions to its customers.

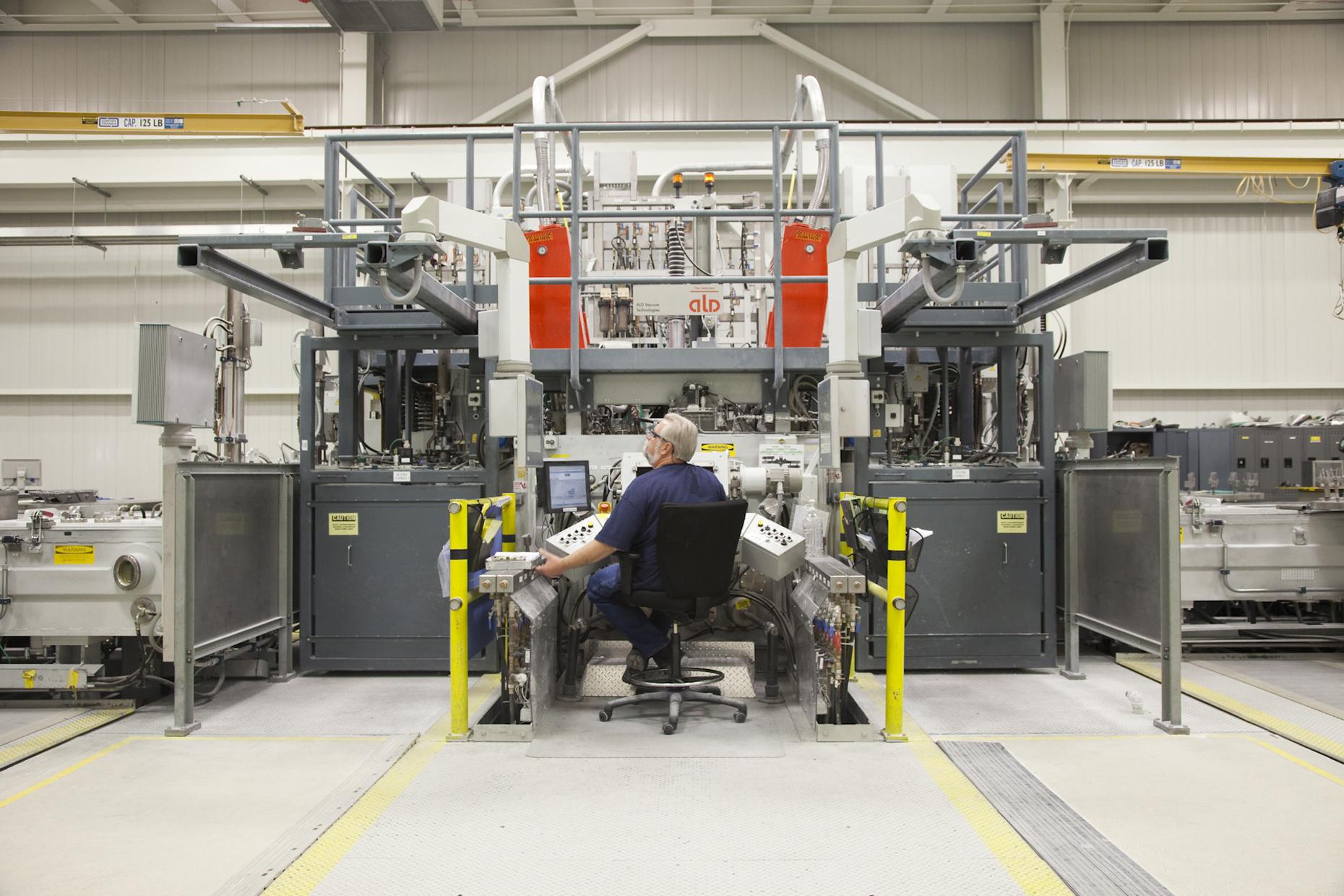

Careers: Praxair Surface Technologies

Praxair Surface Technologies offers a range of career opportunities for professionals in various fields, including engineering, operations, sales, and marketing. The company values its employees and is committed to providing a positive and supportive work environment.

Company Culture

Praxair Surface Technologies fosters a collaborative and innovative work culture that encourages employees to share ideas and work together to achieve common goals. The company promotes diversity and inclusion, believing that a diverse workforce brings a wealth of perspectives and experiences that contribute to its success.

Benefits

Praxair Surface Technologies offers a comprehensive benefits package that includes:

- Competitive salaries and benefits

- Medical, dental, and vision insurance

- Paid time off

- Retirement savings plan

- Employee discounts

- Professional development opportunities

Professional Development

Praxair Surface Technologies is committed to the professional growth and development of its employees. The company offers a variety of training and development programs, including:

- On-the-job training

- Mentorship programs

- Leadership development programs

- Technical training

- Conference and seminar attendance

Final Wrap-Up

As we conclude our exploration of Praxair Surface Technologies, it becomes evident that the company’s unwavering commitment to innovation, customer satisfaction, and sustainability sets it apart as an industry leader. By harnessing the power of advanced surface treatment technologies, Praxair Surface Technologies empowers businesses to unlock new possibilities, optimize performance, and drive sustainable growth.

Frequently Asked Questions

What industries does Praxair Surface Technologies serve?

Praxair Surface Technologies provides surface treatment solutions for a wide range of industries, including aerospace, automotive, energy, and manufacturing.

What are the benefits of using Praxair Surface Technologies’ thermal spray coatings?

Thermal spray coatings from Praxair Surface Technologies offer enhanced wear resistance, corrosion protection, and thermal insulation, leading to improved product performance and extended lifespan.

How does Praxair Surface Technologies contribute to sustainability?

Praxair Surface Technologies prioritizes sustainability through eco-friendly processes and products, minimizing environmental impact while promoting resource conservation.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY