Inventory tracking for small businesses is crucial for efficient operations and profitability. This comprehensive guide delves into the importance, methods, best practices, software, and industry-specific applications of inventory tracking, empowering small businesses to optimize their inventory management.

Inventory Tracking Overview for Small Businesses

Inventory tracking is a crucial aspect of managing a small business. It involves keeping track of the quantity, location, and movement of goods, ensuring that the business has the right amount of stock to meet customer demand while minimizing waste and loss.

Inventory tracking helps businesses improve their operations in several ways. It allows them to:

- Optimize stock levels:Track inventory levels to avoid overstocking or understocking, reducing the risk of lost sales or excess inventory costs.

- Improve forecasting:Use historical inventory data to forecast future demand, enabling businesses to plan for upcoming purchases and avoid stockouts.

- Reduce waste and loss:Identify slow-moving or obsolete items, allowing businesses to adjust their purchasing or marketing strategies to minimize waste and loss.

Benefits of Using Technology for Inventory Tracking

Technology has revolutionized inventory tracking for small businesses. Using inventory management software or mobile apps offers numerous benefits:

- Automated tracking:Software automates inventory updates, reducing manual errors and saving time.

- Real-time visibility:Cloud-based systems provide real-time visibility into inventory levels, allowing businesses to make informed decisions from anywhere.

- Improved accuracy:Automated systems eliminate human error, ensuring more accurate inventory counts.

Methods of Inventory Tracking

Inventory tracking is the process of monitoring the flow of goods within a business. This includes keeping track of the quantity, location, and condition of inventory items.

There are several methods of inventory tracking that small businesses can use, each with its own advantages and disadvantages.

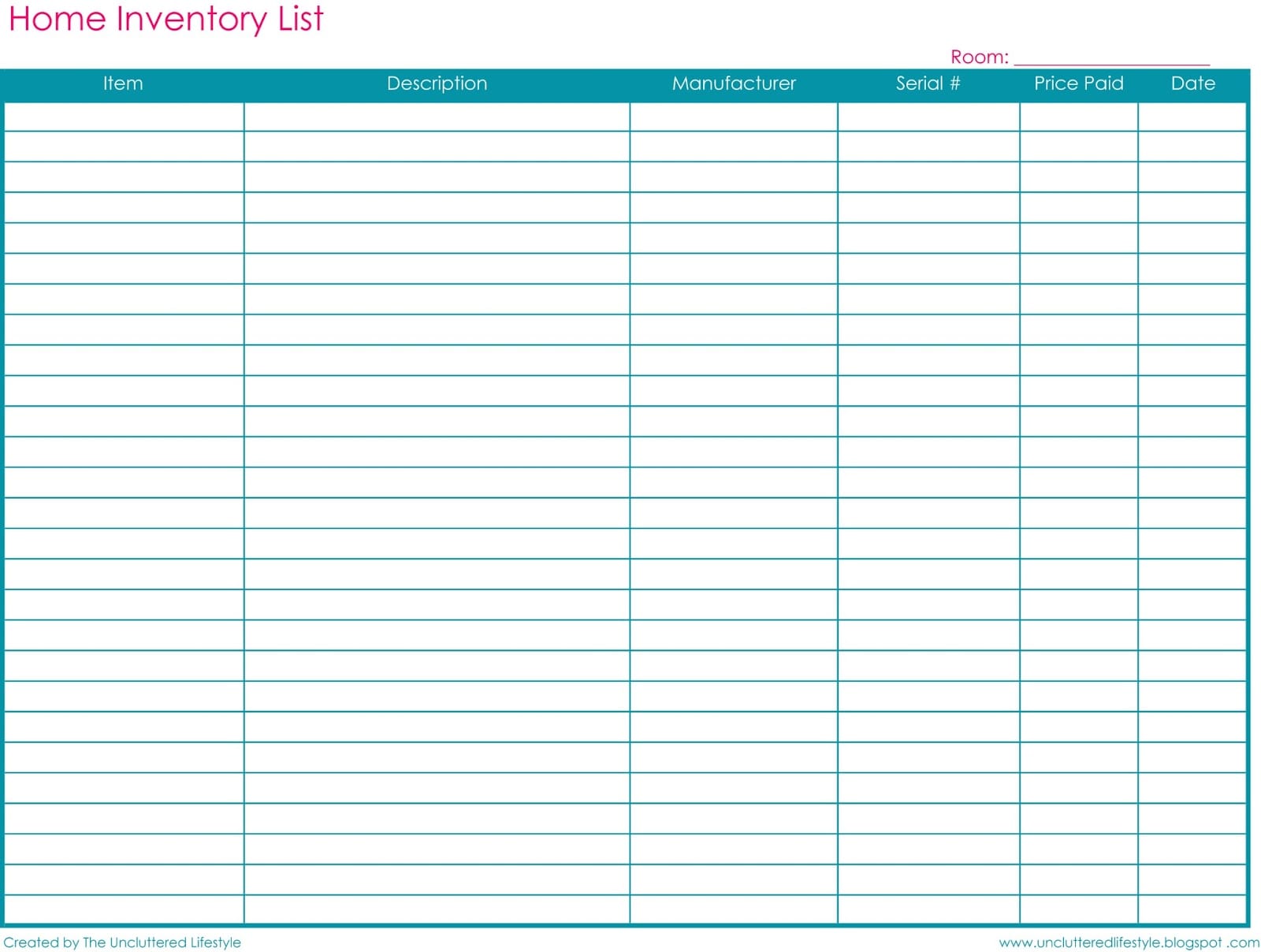

Manual Inventory Tracking

Manual inventory tracking is the most basic method of tracking inventory. It involves using a pen and paper to record the quantity of each item on hand. This method is simple and inexpensive, but it can be time-consuming and error-prone.

- Pros:

- Simple and inexpensive

- Can be used for any type of inventory

- Cons:

- Time-consuming

- Error-prone

- Not scalable

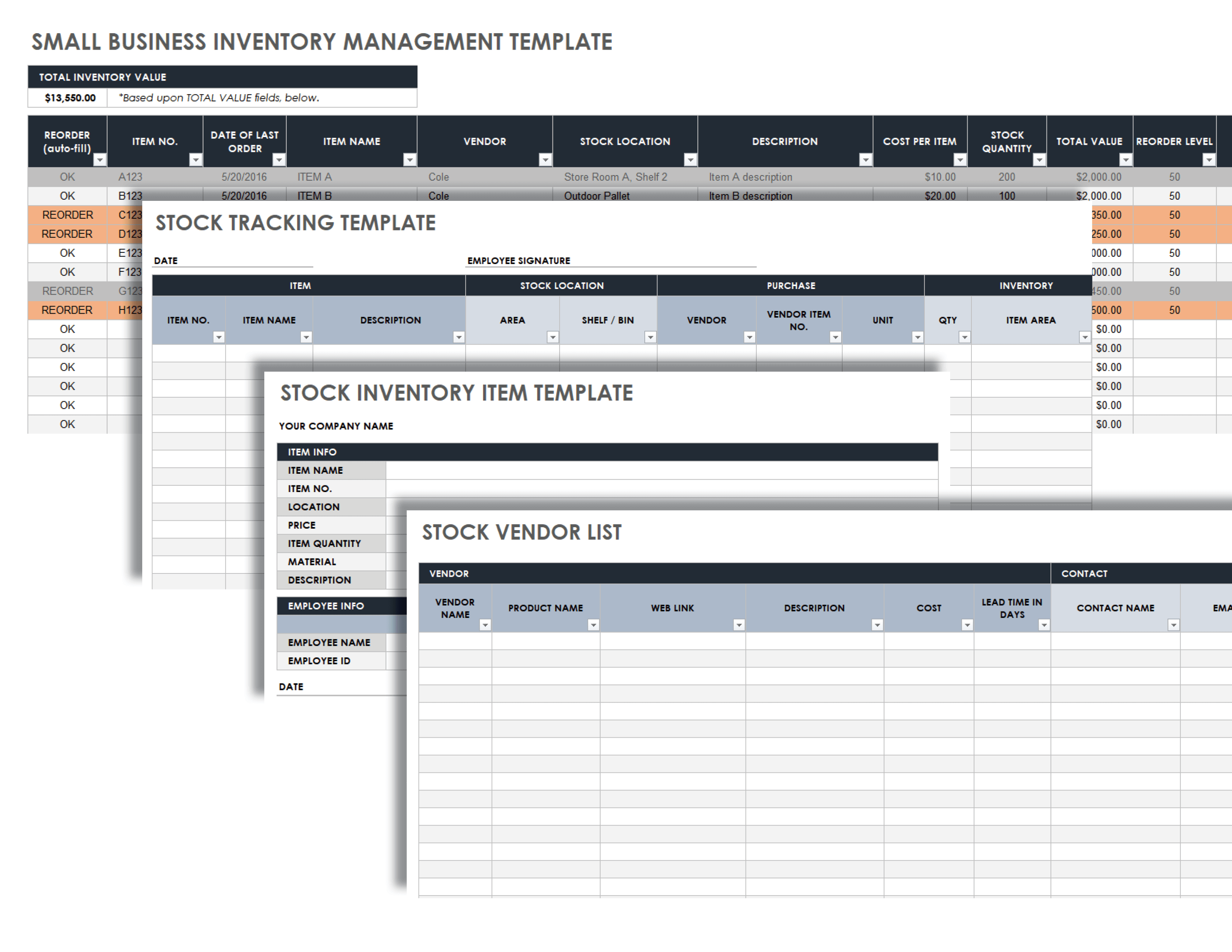

Automated Inventory Tracking

Automated inventory tracking uses software to track the quantity, location, and condition of inventory items. This method is more accurate and efficient than manual inventory tracking, but it can be more expensive.

- Pros:

- Accurate and efficient

- Scalable

- Can be integrated with other business systems

- Cons:

- More expensive than manual inventory tracking

- Requires a computer and software

- May require training to use

Hybrid Inventory Tracking

Hybrid inventory tracking combines elements of both manual and automated inventory tracking. This method can be customized to meet the specific needs of a small business.

- Pros:

- Can be customized to meet the specific needs of a small business

- More accurate and efficient than manual inventory tracking

- Less expensive than automated inventory tracking

- Cons:

- Can be more complex to implement than manual inventory tracking

- May require training to use

Choosing the Best Method for a Small Business

The best method of inventory tracking for a small business will depend on a number of factors, including the size of the business, the type of inventory, and the budget.

Small businesses with a small inventory and a limited budget may find that manual inventory tracking is sufficient. As the business grows and the inventory becomes more complex, an automated or hybrid inventory tracking system may be a better option.

Inventory Tracking Best Practices: Inventory Tracking For Small Business

Effective inventory tracking is crucial for small businesses to maintain optimal stock levels, reduce costs, and prevent losses. Here are some best practices to ensure accurate and efficient inventory management:

Regular Inventory Counts

Conduct regular inventory counts to verify the physical inventory against the records. This helps identify discrepancies, prevent overstocking or shortages, and maintain accurate records.

Cycle Counting, Inventory tracking for small business

Cycle counting involves counting a portion of the inventory regularly instead of the entire stock at once. This allows for more frequent checks, reduces the risk of errors, and helps detect shrinkage early on.

Inventory Valuation

Accurately valuing inventory is essential for financial reporting and profitability analysis. Use appropriate valuation methods (e.g., FIFO, LIFO, weighted average) to determine the value of inventory on hand.

Importance of Accurate Inventory Records

Accurate inventory records are vital for:

- Making informed purchasing decisions

- Preventing stockouts and overstocking

- Optimizing inventory levels and reducing costs

- Ensuring compliance with accounting regulations

Preventing Inventory Shrinkage

Inventory shrinkage refers to the loss of inventory due to theft, damage, or waste. To prevent shrinkage:

- Implement security measures to prevent theft

- Properly store and handle inventory to minimize damage

- Use inventory management software to track inventory movement and identify potential issues

- Regularly review inventory records to identify discrepancies and take corrective action

Inventory Tracking for Different Industries

Inventory tracking is a critical aspect of business operations across various industries. Each industry has unique characteristics and challenges that influence the specific requirements for inventory tracking.

Retail Industry

Retail businesses manage a wide range of products with varying shelf lives and demand patterns. Effective inventory tracking enables retailers to maintain optimal stock levels, prevent overstocking or shortages, and improve customer satisfaction.

- Challenge:Managing high-volume inventory with fluctuating demand and seasonality.

- Consideration:Utilizing real-time inventory tracking systems to monitor stock levels and adjust orders accordingly.

- Case Study:A small clothing store successfully implemented an RFID-based inventory tracking system, reducing inventory discrepancies by 25% and increasing sales by 10%.

Manufacturing Industry

Manufacturers deal with complex production processes involving multiple components and raw materials. Inventory tracking is essential for ensuring smooth production flow, reducing waste, and optimizing supply chain management.

- Challenge:Tracking inventory throughout multiple production stages and warehouses.

- Consideration:Implementing inventory management software with features such as bill of materials (BOM) tracking and real-time stock updates.

- Case Study:A small electronics manufacturer implemented a cloud-based inventory tracking system, improving production efficiency by 15% and reducing inventory holding costs by 20%.

Healthcare Industry

Healthcare facilities require accurate and reliable inventory tracking for critical medical supplies, pharmaceuticals, and equipment. Effective inventory management ensures patient safety, compliance with regulations, and cost optimization.

- Challenge:Managing perishable inventory with varying expiration dates and strict storage requirements.

- Consideration:Using specialized inventory tracking systems designed for healthcare environments, with features such as lot tracking and expiration alerts.

- Case Study:A small hospital implemented a barcoding-based inventory tracking system, reducing medication errors by 30% and improving inventory accuracy by 95%.

Inventory Tracking for E-commerce Businesses

Effective inventory tracking is crucial for e-commerce businesses to ensure accurate order fulfillment, customer satisfaction, and optimal cash flow management.

Challenges of Managing Inventory Across Multiple Channels

E-commerce businesses often sell products through multiple channels, such as their website, online marketplaces, and social media platforms. Managing inventory across these channels can be challenging due to:

- Data synchronization issues:Maintaining real-time inventory data across multiple platforms can be difficult, leading to overselling or understocking.

- Manual processes:Manually tracking inventory across multiple channels is time-consuming and prone to errors.

- Lack of visibility:Businesses may have limited visibility into their inventory levels, making it difficult to make informed decisions about restocking.

Tips for Integrating Inventory Tracking with E-commerce Platforms

To effectively integrate inventory tracking with e-commerce platforms, businesses can follow these tips:

- Choose an inventory management software:Invest in a software solution that integrates with your e-commerce platform and provides real-time inventory updates.

- Automate inventory updates:Set up automated inventory updates to ensure that your e-commerce platform reflects the latest inventory levels.

- Use a central inventory database:Create a central inventory database that all sales channels can access to ensure data consistency.

- Monitor inventory levels regularly:Regularly monitor inventory levels to identify potential shortages or overstocks.

Future Trends in Inventory Tracking

![]()

The future of inventory tracking holds exciting advancements that can revolutionize the way small businesses manage their stock. Emerging technologies, such as RFID (Radio Frequency Identification) and artificial intelligence (AI), are transforming the industry, offering numerous benefits to businesses of all sizes.

RFID technology utilizes radio waves to track items, providing real-time visibility into inventory levels. This eliminates the need for manual counting, reduces errors, and streamlines the entire inventory management process. AI, on the other hand, leverages machine learning algorithms to analyze data, forecast demand, and optimize inventory levels.

This helps businesses minimize overstocking, reduce waste, and improve overall efficiency.

RFID Technology

- Enables real-time tracking of inventory, eliminating manual counting and reducing errors.

- Provides accurate and up-to-date information on inventory levels, allowing businesses to make informed decisions.

- Streamlines the inventory management process, saving time and resources.

Artificial Intelligence

- Analyzes data to forecast demand and optimize inventory levels, minimizing overstocking and waste.

- Identifies trends and patterns, helping businesses anticipate changes in demand and adjust inventory accordingly.

- Automates inventory management tasks, freeing up employees for more strategic initiatives.

As these technologies continue to evolve, they will further enhance the capabilities of inventory tracking systems, providing small businesses with unprecedented visibility and control over their stock. The future of inventory tracking is bright, offering exciting possibilities for businesses to streamline operations, reduce costs, and improve profitability.

Closing Notes

In conclusion, effective inventory tracking is a cornerstone of successful small business operations. By implementing the strategies Artikeld in this guide, small businesses can enhance their efficiency, reduce costs, and gain a competitive edge in the marketplace.

Question Bank

What is the best inventory tracking method for small businesses?

The best method depends on business size, industry, and resources. Manual tracking is suitable for small businesses with limited inventory, while automated systems are more efficient for larger businesses.

How often should I conduct inventory counts?

Regular inventory counts are crucial. The frequency depends on inventory turnover rate, but monthly or quarterly counts are generally recommended.

What are the benefits of using inventory management software?

Inventory management software streamlines tracking, reduces errors, automates tasks, and provides valuable insights for decision-making.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY