Business inventory tracking is the cornerstone of efficient operations, ensuring that businesses have the right products, in the right quantities, at the right time. This comprehensive guide delves into the intricacies of inventory management, exploring methods, technologies, optimization strategies, data analysis, and common challenges faced by businesses.

From manual systems to cutting-edge technologies, we’ll uncover the best practices for optimizing inventory levels, minimizing costs, and improving efficiency. Discover how data analysis can empower businesses to make informed decisions and overcome inventory management hurdles.

Inventory Management Methods

![]()

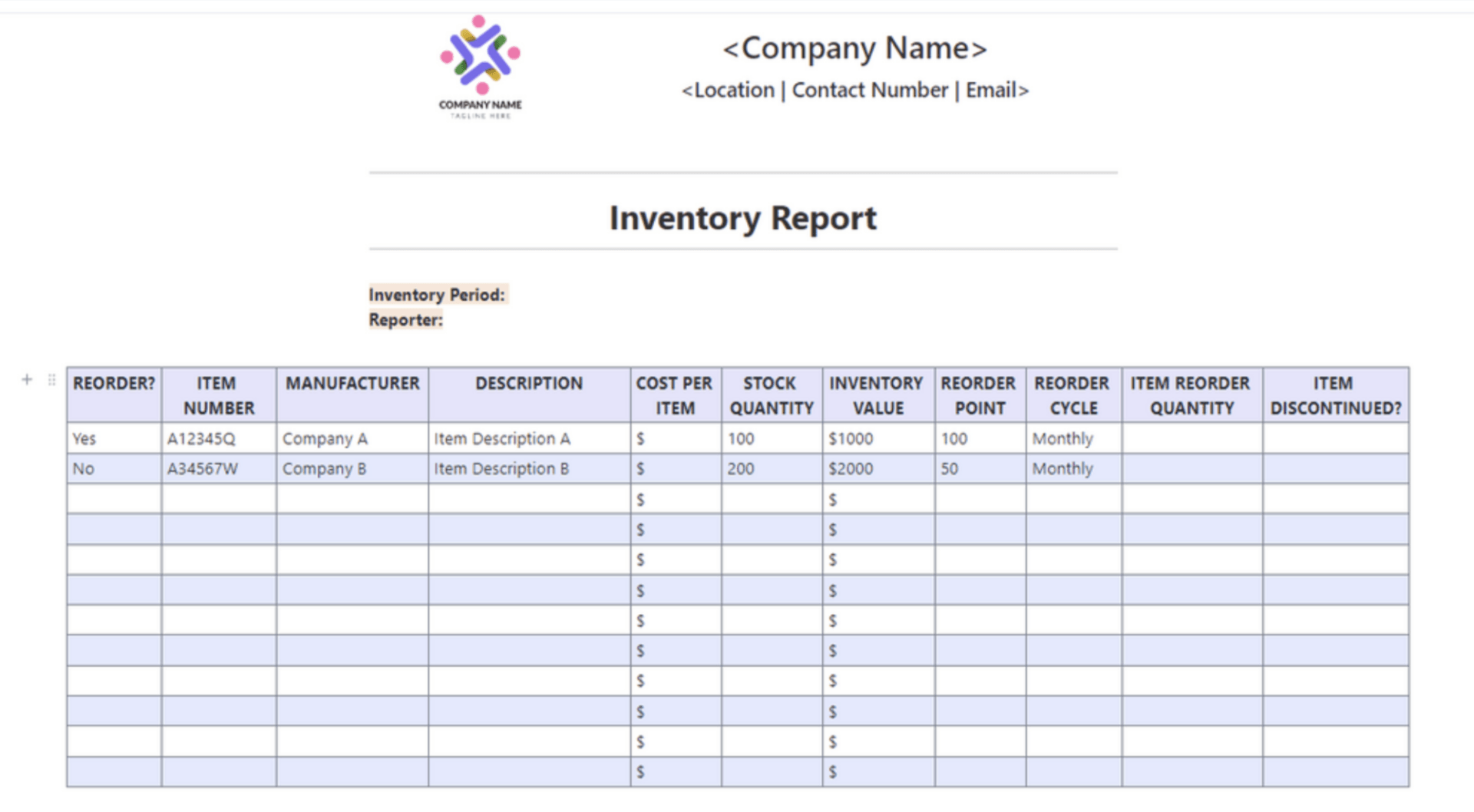

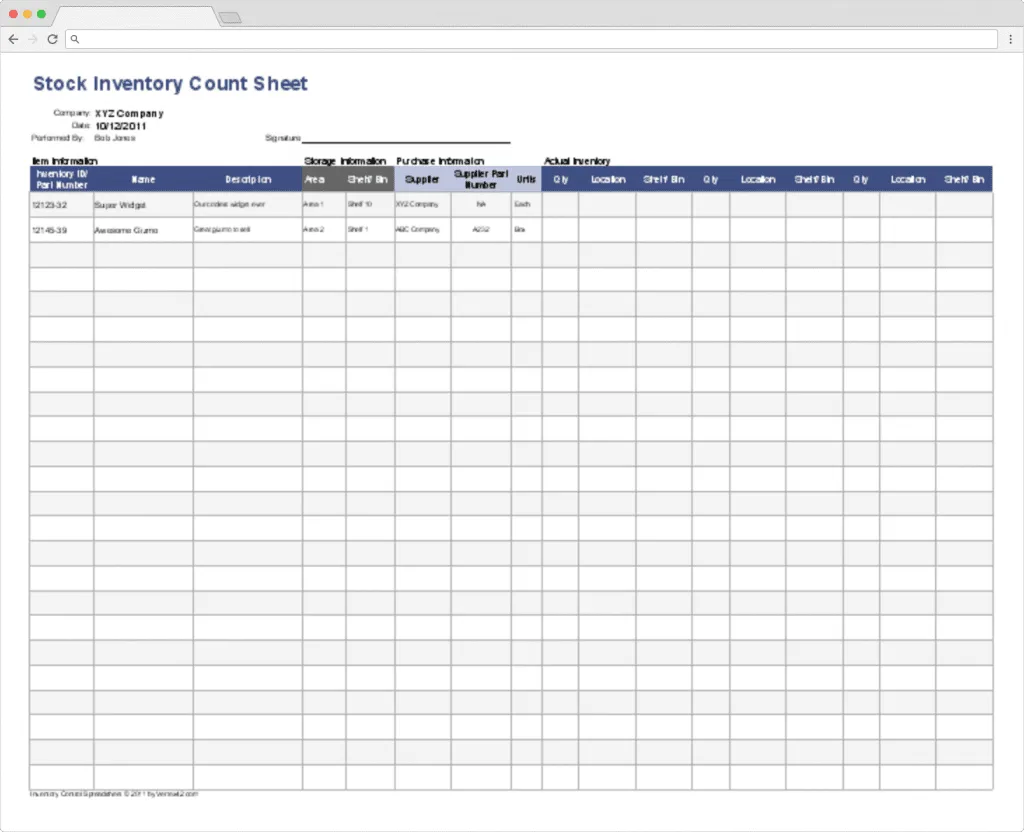

Inventory management is the process of tracking and managing the stock of goods and materials within a business. There are various methods for tracking inventory, each with its own advantages and disadvantages. These methods can be broadly categorized into manual, automated, and hybrid systems.

Manual Inventory Management

Manual inventory management involves tracking inventory manually using pen and paper, spreadsheets, or simple software programs. This method is typically used by small businesses with a limited number of SKUs and low inventory turnover.

Advantages:

- Low cost

- Easy to implement

- Suitable for small businesses with low inventory turnover

Disadvantages:

- Time-consuming and prone to errors

- Difficult to scale as the business grows

- Limited reporting and analysis capabilities

Automated Inventory Management, Business inventory tracking

Automated inventory management systems use software and technology to track inventory in real-time. These systems are typically used by larger businesses with a high volume of SKUs and inventory turnover.

Advantages:

- Accurate and efficient

- Saves time and reduces errors

- Provides real-time visibility into inventory levels

- Supports advanced reporting and analysis

Disadvantages:

- Higher cost

- Requires technical expertise to implement and maintain

- May not be suitable for all businesses

Hybrid Inventory Management

Hybrid inventory management systems combine elements of both manual and automated systems. These systems are typically used by businesses that need the flexibility of a manual system with the accuracy and efficiency of an automated system.

Advantages:

- Cost-effective

- Easy to implement

- Provides greater flexibility than automated systems

Disadvantages:

- More complex to manage than manual systems

- May not be as accurate as automated systems

Inventory Tracking Technologies

In the modern business landscape, accurate and efficient inventory tracking is crucial for optimizing operations and maximizing profitability. Various technologies have emerged to revolutionize inventory management, enabling businesses to gain real-time visibility, improve accuracy, and streamline processes.

Among the most widely adopted inventory tracking technologies are:

Radio Frequency Identification (RFID)

RFID technology utilizes radio waves to identify and track items. RFID tags are attached to individual items or containers, emitting unique signals that are detected by RFID readers. This allows for fast and accurate identification, even in challenging environments like warehouses or retail stores.

RFID systems offer advantages such as:

- Enhanced Accuracy:RFID tags provide highly accurate identification, minimizing errors and discrepancies in inventory records.

- Real-Time Tracking:RFID systems enable real-time visibility of inventory levels, allowing businesses to respond quickly to changes in demand.

- Reduced Labor Costs:Automation of inventory tracking processes through RFID technology reduces the need for manual labor, leading to cost savings.

However, RFID systems can be more expensive to implement and maintain compared to other technologies.

Inventory Optimization Strategies

Inventory optimization is a crucial aspect of inventory management that aims to maintain the right amount of inventory at the right time and at the right cost. By optimizing inventory levels, businesses can minimize costs, improve efficiency, and enhance customer satisfaction.

Inventory optimization involves various strategies and techniques that help businesses forecast demand, determine optimal inventory levels, and manage safety stock. Let’s explore these strategies in more detail.

Inventory Forecasting Techniques

Inventory forecasting is the process of predicting future demand for inventory items. Accurate forecasting is essential for determining optimal inventory levels and avoiding overstocking or stockouts. Common inventory forecasting techniques include:

- Moving Averages: This technique calculates the average demand over a specific period and uses it to forecast future demand.

- Exponential Smoothing: This technique assigns higher weights to more recent data and uses it to smooth out fluctuations in demand.

- Trend Analysis: This technique identifies trends in historical demand data and uses them to project future demand.

Safety Stock

Safety stock is an additional amount of inventory held to buffer against unexpected fluctuations in demand or supply disruptions. The purpose of safety stock is to prevent stockouts and ensure that customer orders can be fulfilled even during peak demand periods or when there are delays in replenishment.

The optimal level of safety stock depends on factors such as the variability of demand, the lead time for replenishment, and the cost of holding inventory.

Inventory Data Analysis

Inventory data analysis is crucial for businesses to assess the efficiency and effectiveness of their inventory management practices. By analyzing key metrics, identifying trends and patterns, and leveraging data-driven insights, businesses can optimize their inventory operations, minimize costs, and enhance customer satisfaction.

Key Inventory Metrics

- Inventory Turnover:Measures how quickly inventory is sold and replaced. A higher turnover rate indicates efficient inventory management.

- Days of Inventory on Hand (DOH):Indicates the average number of days it takes to sell the current inventory. A shorter DOH suggests efficient inventory management.

- Stockout Rate:Represents the percentage of customer orders that cannot be fulfilled due to lack of inventory. A low stockout rate is desirable.

Data Analysis for Trend Identification

Data analysis can reveal valuable insights into inventory management. By tracking metrics over time, businesses can identify trends and patterns that help them make informed decisions. For example, a seasonal increase in demand can be anticipated and planned for, preventing stockouts and lost sales.

Examples of Data Analysis in Practice

- Improved Forecasting:A retail chain used data analysis to identify seasonal patterns and customer preferences. This enabled them to optimize their inventory levels and reduce stockouts by 20%.

- Reduced Carrying Costs:A manufacturing company analyzed inventory turnover data to identify slow-moving items. They reduced their inventory levels of these items, resulting in a 15% reduction in carrying costs.

Inventory Management Challenges: Business Inventory Tracking

Inventory management poses various challenges for businesses, hindering efficient operations and profitability. These challenges include:

Seasonality

Seasonal fluctuations in demand can lead to overstocking during off-seasons and stockouts during peak periods. This can result in lost sales, increased storage costs, and product deterioration.

Mitigation Strategies:

- Forecast demand accurately using historical data and market trends.

- Implement flexible inventory levels that can adjust to seasonal variations.

- Partner with suppliers to ensure timely delivery during peak seasons.

Product Obsolescence

Products that become outdated or obsolete due to technological advancements or changing consumer preferences can lead to inventory write-offs and financial losses.

Mitigation Strategies:

- Monitor industry trends and consumer preferences to identify potential obsolescence.

- Manage inventory levels closely to minimize the risk of holding obsolete products.

- Offer discounts or promotions to clear out obsolete inventory.

Supply Chain Disruptions

Unforeseen events such as natural disasters, geopolitical issues, or transportation delays can disrupt supply chains, leading to inventory shortages or excess.

Mitigation Strategies:

- Establish multiple supplier relationships to reduce reliance on a single source.

- Maintain safety stock levels to buffer against supply chain disruptions.

- Implement contingency plans for alternative transportation routes or production methods.

Case Study: Nike’s Inventory Optimization

Nike successfully overcame inventory challenges by implementing an advanced inventory management system that uses real-time data to forecast demand and optimize inventory levels. This system helped Nike reduce inventory holding costs by 20% while improving customer service levels.

Summary

Mastering business inventory tracking is a journey of continuous improvement. By embracing the strategies Artikeld in this guide, businesses can streamline their operations, reduce waste, and gain a competitive edge. Remember, inventory management is not just about counting stock; it’s about optimizing resources, ensuring customer satisfaction, and driving business success.

Q&A

What are the benefits of using inventory management software?

Inventory management software streamlines inventory tracking, automates processes, provides real-time visibility, and enhances decision-making.

How can RFID technology improve inventory accuracy?

RFID tags allow for contactless identification and tracking of items, significantly reducing errors and improving inventory accuracy.

What is the importance of inventory forecasting?

Inventory forecasting helps businesses predict future demand, optimize stock levels, and avoid overstocking or understocking.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY