In the competitive landscape of modern business, a robust business inventory system is an indispensable tool. By leveraging technology to optimize inventory levels, businesses can streamline operations, enhance accuracy, and gain a strategic advantage. This comprehensive guide delves into the fundamentals, benefits, types, and emerging trends of business inventory systems, empowering businesses to make informed decisions and elevate their inventory management practices.

Effective inventory management is not merely about tracking stock levels; it encompasses a wide range of techniques and technologies that enable businesses to optimize inventory levels, reduce waste, and improve overall efficiency. By understanding the core concepts and best practices of inventory management, businesses can unlock significant value and gain a competitive edge in their respective industries.

Inventory Management Fundamentals

Inventory management is the process of managing the flow of goods from the point of origin to the point of consumption. It involves planning, acquiring, storing, and distributing inventory to meet customer demand while minimizing costs.

There are three main types of inventory systems: periodic, perpetual, and just-in-time (JIT). Periodic inventory systems are updated at regular intervals, such as monthly or quarterly. Perpetual inventory systems are updated in real-time as transactions occur. JIT systems are designed to minimize inventory levels by only ordering what is needed, when it is needed.

Businesses use inventory management systems to improve their efficiency and profitability. By optimizing inventory levels, businesses can reduce costs, improve customer service, and increase sales.

Inventory Management Goals

- Minimize inventory costs

- Improve customer service

- Increase sales

Benefits of Business Inventory Systems

Implementing a business inventory system offers a multitude of advantages that streamline operations, enhance efficiency, and improve accuracy.

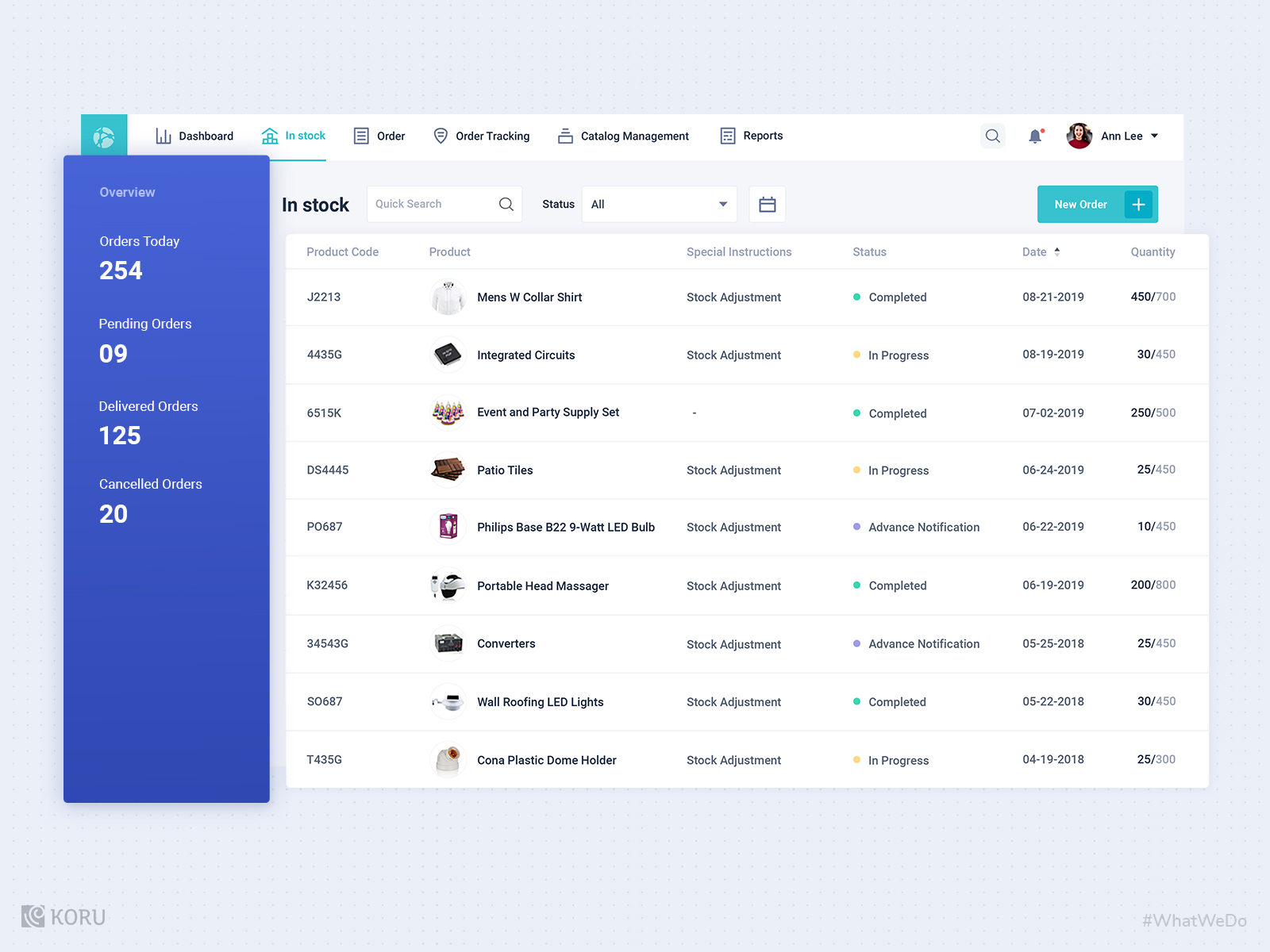

These systems provide businesses with real-time visibility into their inventory levels, enabling them to make informed decisions about restocking, production, and sales. By automating inventory management tasks, businesses can reduce manual errors, save time, and improve overall efficiency.

Improved Efficiency

- Automated inventory tracking reduces manual labor and eliminates the need for manual counting.

- Centralized inventory data provides real-time visibility, allowing for quick and accurate order fulfillment.

- Streamlined inventory processes improve communication and coordination between departments.

Enhanced Accuracy

- Automatic data entry minimizes errors and ensures data integrity.

- Regular inventory audits verify accuracy and identify discrepancies.

- Improved data accuracy leads to better decision-making and reduced losses.

Case Study: ABC Company

ABC Company, a leading retailer, implemented a business inventory system that resulted in significant improvements. The system automated inventory tracking, reducing manual counting time by 50%. This freed up staff for other value-added tasks, such as customer service and sales.

Additionally, the improved accuracy led to a 15% reduction in inventory shrinkage.

Types of Business Inventory Systems

Business inventory systems are crucial for managing stock levels, ensuring efficient operations, and optimizing profitability. Different types of inventory systems cater to specific business needs and industry requirements. Understanding the features, advantages, and disadvantages of each system is essential for businesses to make informed decisions and choose the most suitable solution.

Inventory System Types, Business inventory system

The following table summarizes the key types of business inventory systems:

| Inventory System Type | Features | Advantages | Disadvantages | Examples |

|---|---|---|---|---|

| Periodic Inventory System | – Physical inventory counts conducted periodically (e.g., monthly, quarterly)

|

– Provides accurate inventory data at specific points in time

|

– Time-consuming and labor-intensive

|

– Small businesses

|

| Perpetual Inventory System | – Real-time tracking of inventory levels

|

– Provides up-to-date inventory information

|

– Requires accurate data entry and maintenance

|

– Warehouses

|

| Just-in-Time (JIT) Inventory System | – Inventory is ordered and received only when needed

|

– Reduces inventory waste and storage costs

|

– Requires reliable suppliers and efficient logistics

|

– Manufacturing plants

|

| Consignment Inventory System | – Inventory is owned by the supplier but stored at the customer’s location

|

– Reduces inventory carrying costs for the customer

|

– Customer has less control over inventory

|

– Retail stores

|

| Drop Shipping Inventory System | – Customer orders are shipped directly from the supplier to the customer

|

– Minimal inventory management and storage costs

|

– Less control over product quality and delivery

|

– Online retailers

|

Inventory Management Techniques

Effective inventory management involves implementing strategies to optimize inventory levels, reduce waste, and enhance overall efficiency. Businesses can leverage various techniques to achieve these goals, including:

Just-in-Time (JIT) Inventory

JIT aims to minimize inventory by only ordering and receiving items when needed. This reduces holding costs and ensures that inventory is fresh and relevant to current demand.

First-In, First-Out (FIFO) Inventory

FIFO assumes that the first items received are the first to be sold or used. This helps prevent inventory from becoming outdated or obsolete, ensuring that older items are sold before newer ones.

Last-In, First-Out (LIFO) Inventory

LIFO assumes that the last items received are the first to be sold or used. This can be advantageous during periods of inflation, as it allows businesses to recognize higher costs of goods sold, potentially reducing tax liability.

Economic Order Quantity (EOQ)

EOQ is a formula that helps businesses determine the optimal quantity to order at a time. It considers factors such as demand, ordering costs, and holding costs to minimize total inventory costs.

Safety Stock

Safety stock refers to the additional inventory held to buffer against unexpected fluctuations in demand or supply chain disruptions. It helps prevent stockouts and ensures that businesses can meet customer needs even during peak periods.

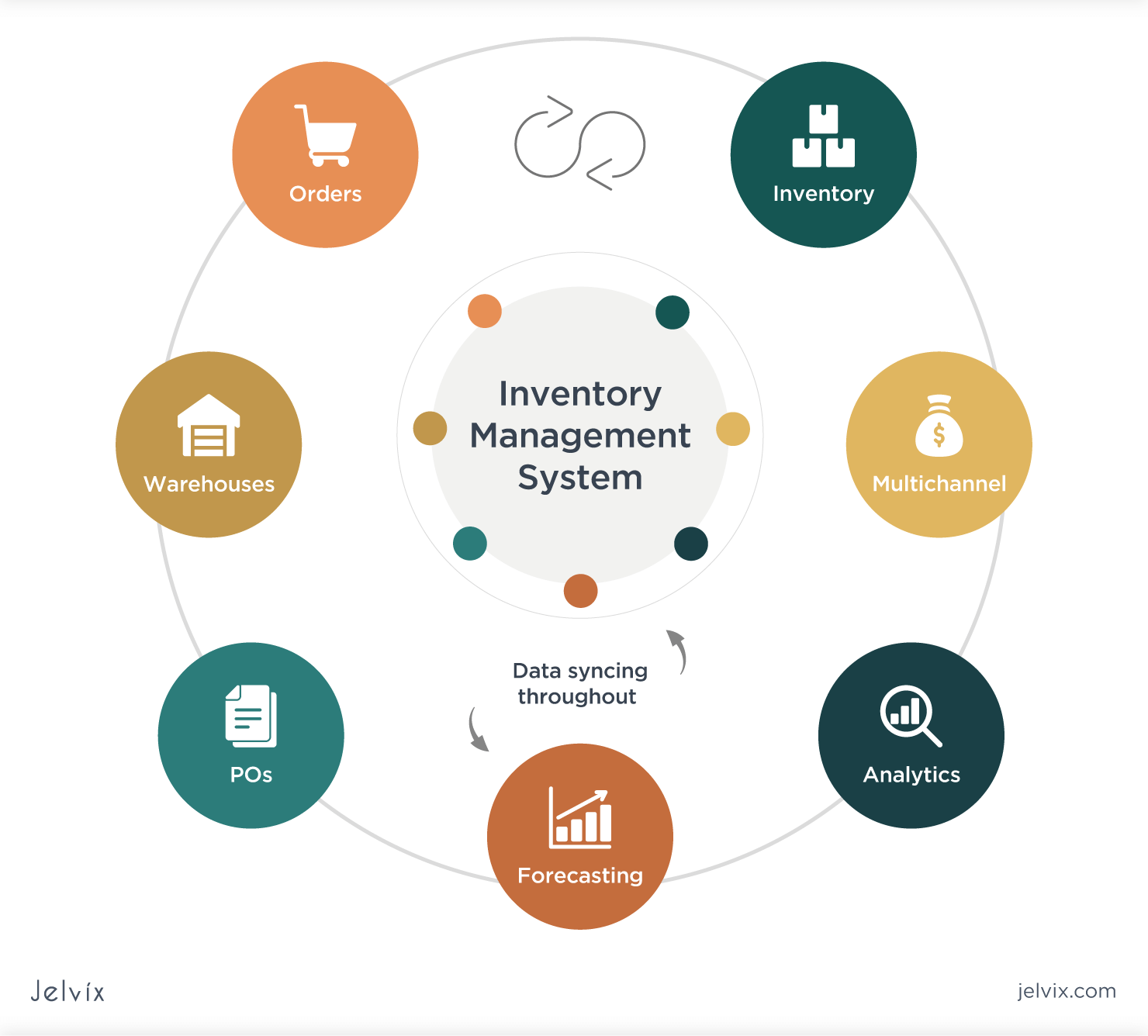

Inventory Control and Tracking

Inventory control and tracking are essential processes for businesses to maintain accurate records of their inventory levels, optimize stock management, and prevent losses. Various methods and technologies are employed to effectively control and track inventory.

One common method is physical inventory counting, where inventory items are manually counted and recorded at regular intervals. This method provides a snapshot of inventory levels at a specific point in time.

Barcodes and RFID

Barcodes and radio frequency identification (RFID) are widely used technologies for inventory tracking. Barcodes are machine-readable labels that store product information, allowing for quick and accurate scanning and data capture. RFID tags are small electronic devices that transmit data wirelessly, providing real-time inventory visibility and tracking.

Inventory Reconciliation and Cycle Counting

Inventory reconciliation involves comparing physical inventory counts with inventory records to identify discrepancies and ensure accuracy. Cycle counting is a periodic process where a portion of the inventory is counted and reconciled on a rotating basis, rather than counting the entire inventory at once.

Inventory Forecasting and Replenishment

Inventory forecasting and replenishment are crucial aspects of inventory management, enabling businesses to predict future demand and optimize stock levels to meet customer needs while minimizing costs.

Accurate forecasting helps businesses anticipate demand fluctuations, plan production schedules, and make informed decisions about inventory replenishment to avoid stockouts or excessive inventory.

Forecasting Techniques

Various forecasting techniques can be employed, each with its advantages and applications:

- Moving Average:Calculates an average of historical demand over a specified period, providing a simple and intuitive forecast.

- Exponential Smoothing:Similar to moving average but assigns higher weights to more recent data, making it more responsive to demand changes.

- Trend Analysis:Identifies trends in historical demand to project future demand based on past patterns.

- Regression Analysis:Uses statistical models to identify relationships between demand and independent variables, such as seasonality or economic indicators.

Reorder Points and Safety Stock

Based on forecasts, businesses establish reorder points, the inventory level at which new orders are placed, and safety stock levels, a buffer to mitigate demand variability.

- Reorder Point:Calculated as the sum of average daily demand during lead time (time between placing an order and receiving it) and safety stock.

- Safety Stock:A buffer to protect against unexpected demand surges or supply chain disruptions. Setting appropriate safety stock levels is crucial to avoid stockouts while minimizing inventory carrying costs.

Inventory Valuation and Costing: Business Inventory System

Inventory valuation is the process of determining the value of inventory on hand at a given point in time. This is important for financial reporting purposes, as inventory is a major asset for many businesses.

There are a number of different methods of inventory valuation, each with its own advantages and disadvantages. The most common methods are:

- First-in, first-out (FIFO)

- Last-in, first-out (LIFO)

- Weighted average cost

The choice of inventory valuation method can have a significant impact on a company’s financial statements. For example, FIFO will result in higher inventory values during periods of rising prices, while LIFO will result in lower inventory values during periods of rising prices.

Inventory Costing Techniques

Inventory costing techniques are used to assign costs to inventory items. This is important for determining the cost of goods sold and the value of inventory on hand.

The most common inventory costing techniques are:

- Specific identification

- Average cost

- First-in, first-out (FIFO)

- Last-in, first-out (LIFO)

The choice of inventory costing technique can have a significant impact on a company’s financial statements. For example, specific identification will result in the most accurate cost of goods sold, while FIFO will result in the lowest cost of goods sold.

Emerging Trends in Inventory Management

Inventory management is constantly evolving, driven by technological advancements and changing business needs. Here are some emerging trends shaping the future of inventory management:

Artificial Intelligence (AI)

- Predictive analytics: AI algorithms analyze historical data to forecast demand, optimize inventory levels, and prevent stockouts.

- Automated inventory replenishment: AI-powered systems can automatically trigger purchase orders when inventory falls below certain thresholds.

- Improved inventory accuracy: AI can be used to monitor inventory levels in real-time, reducing errors and discrepancies.

Internet of Things (IoT)

- Real-time inventory tracking: IoT devices, such as RFID tags and sensors, provide real-time visibility into inventory levels, enabling businesses to track items throughout the supply chain.

- Automated data collection: IoT devices can automatically collect data on inventory levels, location, and condition, eliminating the need for manual data entry.

- Improved inventory control: IoT enables businesses to monitor and control inventory levels remotely, ensuring optimal stock levels and reducing the risk of overstocking or understocking.

Future of Inventory Management

The future of inventory management will be characterized by increased automation, data-driven decision-making, and a focus on sustainability:

- Automated inventory management systems: AI and IoT will drive the development of fully automated inventory management systems that minimize human intervention and errors.

- Data-driven insights: Businesses will leverage data analytics to gain insights into inventory patterns, demand trends, and supply chain performance, enabling them to make informed decisions.

- Sustainability: Inventory management will increasingly focus on reducing waste and optimizing resource utilization, aligning with sustainability goals.

Conclusion

As businesses navigate the ever-evolving landscape of inventory management, embracing emerging technologies and adopting data-driven approaches will be crucial for success. By leveraging the insights provided in this guide, businesses can transform their inventory management practices, enhance operational efficiency, and unlock new opportunities for growth.

The future of inventory management holds immense potential, and those who embrace innovation and best practices will be well-positioned to reap its rewards.

Top FAQs

What are the key benefits of implementing a business inventory system?

Business inventory systems offer numerous benefits, including improved accuracy, reduced waste, enhanced efficiency, better customer service, and increased profitability.

What are the different types of business inventory systems?

There are various types of business inventory systems, each with its own advantages and disadvantages. Common types include periodic inventory systems, perpetual inventory systems, and just-in-time (JIT) inventory systems.

How can businesses optimize inventory levels and reduce waste?

Businesses can optimize inventory levels and reduce waste by implementing inventory management techniques such as safety stock, reorder points, and inventory forecasting.

What are the emerging trends in inventory management?

Emerging trends in inventory management include the use of artificial intelligence (AI), the Internet of Things (IoT), and cloud-based inventory management solutions.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY