Business inventory management and stock control – In the realm of business, inventory management and stock control are indispensable functions that can significantly impact profitability, customer satisfaction, and overall operational efficiency. This comprehensive guide delves into the intricacies of these crucial processes, empowering you with the knowledge and strategies to optimize your inventory practices.

Effective inventory management ensures that businesses have the right products, in the right quantities, at the right time. It involves a delicate balance between minimizing carrying costs and maintaining sufficient stock levels to meet customer demand. By implementing robust stock control methods, businesses can prevent stockouts, reduce waste, and enhance their supply chain agility.

Definition and Overview

Business inventory management and stock control refer to the processes involved in managing the flow of goods within a business, from the point of acquisition to the point of sale or distribution.

Effective inventory management is crucial for businesses as it helps optimize stock levels, reduce waste, improve customer service, and enhance overall operational efficiency.

Importance of Effective Inventory Management

- Prevents stockouts:Adequate inventory levels ensure that businesses can meet customer demand and avoid lost sales due to stock shortages.

- Reduces waste:Effective inventory management helps businesses minimize overstocking, which can lead to spoilage, obsolescence, and increased storage costs.

- Improves customer satisfaction:When businesses have the right products in stock, they can fulfill orders promptly and efficiently, leading to improved customer satisfaction.

- Optimizes cash flow:Proper inventory management helps businesses avoid tying up excessive capital in inventory, freeing up cash for other business needs.

- Enhances operational efficiency:Efficient inventory management streamlines business processes, reduces manual errors, and improves overall operational productivity.

Inventory Management Techniques

Inventory management techniques are strategies and methods used to optimize the storage and flow of inventory within a business. These techniques aim to minimize costs, improve efficiency, and ensure product availability while maintaining desired service levels.

There are several inventory management techniques, each with its advantages and disadvantages. The choice of technique depends on the specific industry, product characteristics, and business objectives.

First-in, First-out (FIFO)

FIFO is an inventory management technique that assumes that the first items purchased are the first to be sold. This means that the oldest inventory is sold first, followed by the newer inventory.

- Advantages:

- Ensures a consistent flow of inventory.

- Prevents obsolete inventory from accumulating.

- Facilitates accurate cost accounting.

- Disadvantages:

- Can result in higher inventory costs during periods of rising prices.

- May not be suitable for perishable goods.

Last-in, First-out (LIFO), Business inventory management and stock control

LIFO is an inventory management technique that assumes that the last items purchased are the first to be sold. This means that the newest inventory is sold first, followed by the older inventory.

- Advantages:

- Can reduce inventory costs during periods of rising prices.

- May be suitable for perishable goods.

- Disadvantages:

- Can result in lower inventory costs during periods of falling prices.

- May not be suitable for accurate cost accounting.

Just-in-Time (JIT)

JIT is an inventory management technique that aims to minimize inventory levels by receiving goods only when they are needed for production or sale. This technique requires close coordination with suppliers and a reliable supply chain.

- Advantages:

- Reduces inventory costs.

- Improves inventory turnover.

- Frees up capital for other business purposes.

- Disadvantages:

- Requires a high level of coordination and planning.

- Can be disrupted by supply chain disruptions.

- May not be suitable for all industries or products.

Stock Control Methods

Stock control is the process of managing the levels of inventory on hand. There are a number of different stock control methods that businesses can use, each with its own benefits and drawbacks.

Periodic Inventory System

The periodic inventory system is a simple method of stock control that involves taking a physical count of inventory at regular intervals, such as monthly or quarterly. This method is relatively inexpensive to implement, but it can be time-consuming and inaccurate.

Perpetual Inventory System

The perpetual inventory system is a more complex method of stock control that involves tracking inventory levels on a continuous basis. This method is more accurate than the periodic inventory system, but it is also more expensive to implement.

Cycle Counting

Cycle counting is a hybrid stock control method that involves taking a physical count of a portion of inventory on a regular basis. This method is less time-consuming than the periodic inventory system, and it is more accurate than the perpetual inventory system.

Inventory Management Systems

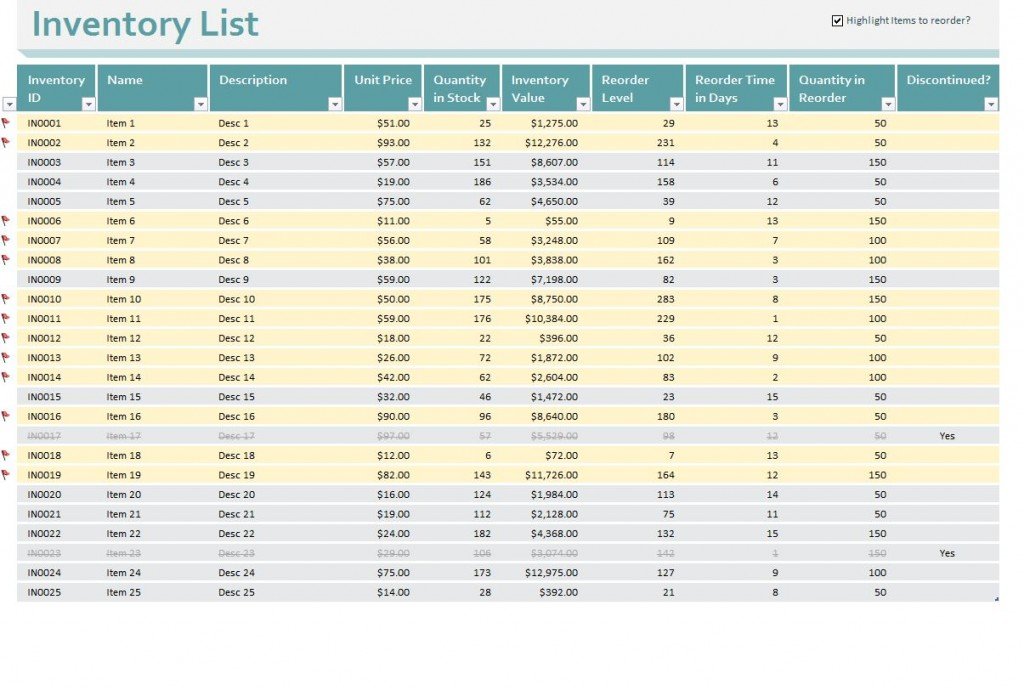

Inventory management systems are crucial tools that help businesses optimize their inventory levels, reduce costs, and improve operational efficiency. These systems provide real-time visibility into inventory data, enabling businesses to make informed decisions about stock levels, replenishment, and distribution.

There are numerous inventory management software solutions available, each with its unique features and capabilities. Some popular options include:

Examples of Inventory Management Software

- SAP S/4HANA:A comprehensive ERP system that includes robust inventory management capabilities.

- Oracle NetSuite:A cloud-based inventory management solution suitable for businesses of all sizes.

- Microsoft Dynamics 365 Supply Chain Management:A cloud-based solution that integrates inventory management with other supply chain processes.

- Infor CloudSuite Inventory:A cloud-based inventory management system designed for manufacturing and distribution businesses.

- Fishbowl Inventory:A desktop-based inventory management solution suitable for small businesses.

Benefits of Effective Inventory Management

Effective inventory management practices bring about numerous advantages for businesses, including:

Reduced carrying costs:

- Holding excess inventory ties up valuable capital, resulting in higher storage, insurance, and handling costs.

- Effective inventory management helps businesses optimize stock levels, reducing carrying costs and freeing up capital for other investments.

Improved customer service:

- Effective inventory management ensures businesses have the right products in stock to meet customer demand.

- This reduces stockouts, backorders, and delays, leading to improved customer satisfaction and loyalty.

Increased efficiency and productivity:

- Efficient inventory management streamlines operations, reducing time and resources spent on inventory-related tasks.

- This frees up staff to focus on other value-added activities, increasing overall productivity.

Challenges in Inventory Management

Inventory management is a crucial aspect of supply chain management, but it comes with its fair share of challenges. Businesses often face difficulties in forecasting demand accurately, managing obsolete or excess inventory, and dealing with inventory shrinkage.

Forecasting Demand Accurately

Forecasting demand accurately is essential for maintaining optimal inventory levels. However, it can be a complex task influenced by various factors such as market trends, seasonality, and customer behavior. Inaccurate demand forecasts can lead to overstocking or understocking, both of which can result in lost sales, increased costs, and reduced profitability.

Managing Obsolete or Excess Inventory

Obsolete or excess inventory refers to items that are no longer in demand or have exceeded their shelf life. Holding on to such inventory ties up valuable resources, increases storage costs, and can lead to spoilage or obsolescence. Managing obsolete or excess inventory requires careful planning and strategies such as markdowns, promotions, or liquidation.

Dealing with Inventory Shrinkage

Inventory shrinkage refers to the loss of inventory due to theft, damage, or administrative errors. It can significantly impact a business’s profitability and reputation. Dealing with inventory shrinkage requires implementing effective security measures, conducting regular inventory audits, and training staff on proper inventory handling procedures.

Best Practices for Inventory Management: Business Inventory Management And Stock Control

Implementing best practices in inventory management is crucial for optimizing inventory levels, minimizing costs, and improving customer satisfaction. Here are some guidelines to follow:

Setting Inventory Targets

Determine optimal inventory levels based on factors such as demand forecasts, lead times, and safety stock requirements. Set clear targets for each item, considering both minimum and maximum stock levels.

Establishing Safety Stock Levels

Maintain a buffer of safety stock to mitigate unexpected demand fluctuations or supply chain disruptions. Calculate safety stock levels based on historical demand variability and lead times.

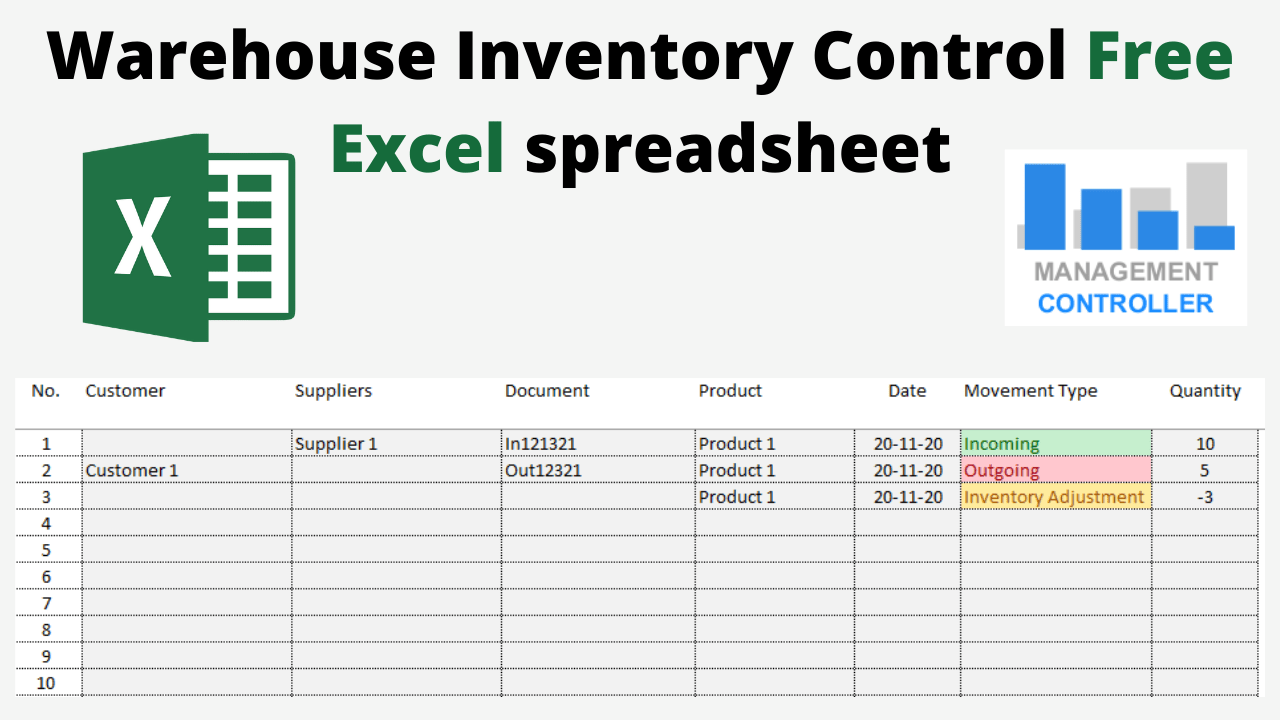

Using Technology to Optimize Inventory Processes

Leverage technology solutions to streamline inventory management processes, such as inventory management software, automated replenishment systems, and data analytics tools. These technologies can enhance visibility, improve accuracy, and optimize inventory levels.

Closure

Mastering business inventory management and stock control is a continuous journey that requires ongoing evaluation and adaptation to changing market conditions. By embracing best practices, leveraging technology, and staying abreast of industry trends, businesses can unlock the full potential of these processes and gain a competitive edge in today’s dynamic business landscape.

Answers to Common Questions

What are the key benefits of effective inventory management?

Effective inventory management can reduce carrying costs, improve customer service, increase efficiency and productivity, and minimize the risk of stockouts and excess inventory.

What are the different inventory management techniques?

Common inventory management techniques include First-In, First-Out (FIFO), Last-In, First-Out (LIFO), and Just-In-Time (JIT).

How can technology enhance inventory management?

Inventory management systems and software can automate inventory processes, provide real-time visibility, and facilitate data analysis to optimize inventory levels and improve decision-making.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY