As business inventories Y AE take center stage, understanding their importance in supply chain management becomes paramount. This comprehensive guide delves into the intricacies of inventory management, exploring various types, valuation methods, control techniques, and optimization strategies. With real-world examples and industry-specific insights, we unravel the complexities of inventory management, empowering businesses to maximize efficiency and drive success.

Inventory management plays a pivotal role in ensuring a seamless flow of goods and services, optimizing costs, and meeting customer demand. It encompasses a wide range of activities, from tracking inventory levels to implementing control systems and leveraging technology for greater accuracy and efficiency.

By delving into the nuances of business inventories Y AE, we equip businesses with the knowledge and tools to navigate the complexities of supply chain management and achieve operational excellence.

Business Inventory Management

Business inventories are crucial for supply chain management, representing the raw materials, work-in-progress goods, and finished products held by a company. Effective inventory management ensures a steady flow of goods, minimizes costs, and meets customer demand.

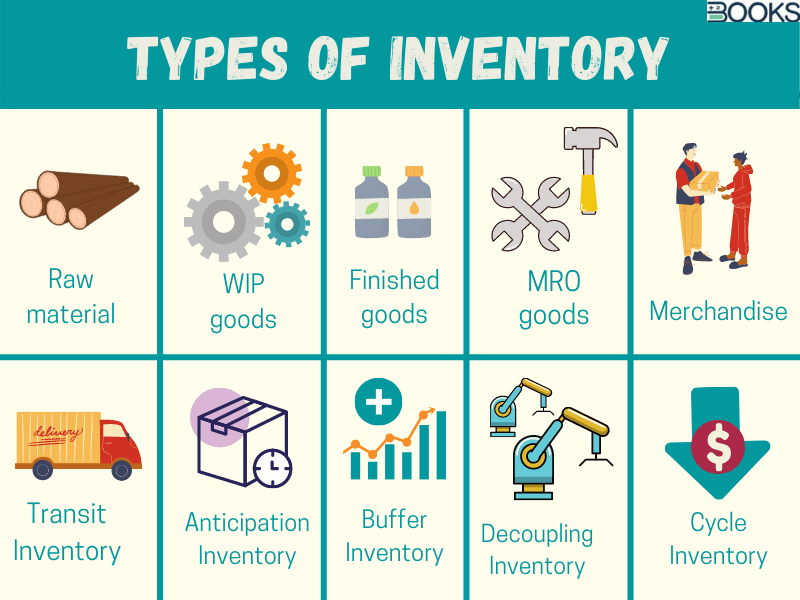

Types of Inventories

Inventories are classified into various types based on their purpose and stage in the production process:

- Raw materials inventory:Unprocessed materials used to produce goods.

- Work-in-progress inventory:Partially completed goods undergoing production.

- Finished goods inventory:Completed products ready for sale.

- Safety stock inventory:Additional inventory held to buffer against unexpected demand or supply disruptions.

- Seasonal inventory:Inventory accumulated to meet specific seasonal demands.

Inventory Valuation Methods

Inventory valuation methods are the techniques used to determine the value of inventory on hand at a specific point in time. There are several different methods that can be used, each with its own advantages and disadvantages.

The most common inventory valuation methods are:

- First-in, first-out (FIFO)

- Last-in, first-out (LIFO)

- Weighted average cost

- Specific identification

First-in, First-out (FIFO)

FIFO assumes that the first inventory purchased is the first inventory sold. This method results in the oldest inventory being valued at the lowest cost, which can lead to higher profits in periods of rising prices.

Advantages of FIFO:

- Easy to implement

- Provides a more accurate representation of the current cost of inventory

Disadvantages of FIFO:

- Can lead to lower profits in periods of falling prices

- Can result in inventory being overvalued

Last-in, First-out (LIFO)

LIFO assumes that the last inventory purchased is the first inventory sold. This method results in the newest inventory being valued at the lowest cost, which can lead to lower profits in periods of rising prices.

Advantages of LIFO:

- Can lead to higher profits in periods of falling prices

- Can result in inventory being undervalued

Disadvantages of LIFO:

- More difficult to implement than FIFO

- Can lead to lower profits in periods of rising prices

Weighted Average Cost

Weighted average cost assumes that all inventory is purchased at the same cost. This method results in the average cost of inventory being used to value all inventory on hand.

Advantages of weighted average cost:

- Easy to implement

- Provides a more stable cost of inventory over time

Disadvantages of weighted average cost:

- Can be less accurate than FIFO or LIFO

- Can result in inventory being overvalued or undervalued

Specific Identification

Specific identification assumes that each unit of inventory is tracked and valued individually. This method is the most accurate, but it is also the most difficult to implement.

Advantages of specific identification:

- Most accurate method of inventory valuation

- Allows for the tracking of individual inventory items

Disadvantages of specific identification:

- Difficult to implement

- Can be time-consuming

| Inventory Valuation Method | Advantages | Disadvantages |

|---|---|---|

| FIFO | Easy to implementProvides a more accurate representation of the current cost of inventory | Can lead to lower profits in periods of falling pricesCan result in inventory being overvalued |

| LIFO | Can lead to higher profits in periods of falling pricesCan result in inventory being undervalued | More difficult to implement than FIFOCan lead to lower profits in periods of rising prices |

| Weighted Average Cost | Easy to implementProvides a more stable cost of inventory over time | Can be less accurate than FIFO or LIFOCan result in inventory being overvalued or undervalued |

| Specific Identification | Most accurate method of inventory valuationAllows for the tracking of individual inventory items | Difficult to implementCan be time-consuming |

Inventory Control Techniques

Inventory control techniques are crucial for businesses to effectively manage their inventory levels, minimize costs, and ensure efficient operations. These techniques help businesses maintain optimal inventory levels, preventing overstocking or understocking, which can lead to lost sales or excessive holding costs.Key inventory control techniques include:

- Cycle counting:Periodically counting inventory to verify its accuracy and identify any discrepancies.

- ABC analysis:Categorizing inventory items based on their value and usage to prioritize inventory management efforts.

- Just-in-time (JIT) inventory:Maintaining minimal inventory levels and replenishing stock only when needed to reduce holding costs.

- First-in, first-out (FIFO) inventory valuation:Assuming that the oldest inventory is sold first, resulting in a more accurate representation of current inventory costs.

- Last-in, first-out (LIFO) inventory valuation:Assuming that the most recently acquired inventory is sold first, potentially reducing taxable income in inflationary periods.

Benefits of Inventory Control Techniques

Implementing inventory control techniques offers numerous benefits, including:

- Reduced inventory costs by minimizing overstocking and spoilage.

- Improved customer satisfaction by ensuring product availability and reducing lead times.

- Enhanced operational efficiency by streamlining inventory management processes.

- Increased profitability by optimizing inventory levels and reducing carrying costs.

- Improved inventory accuracy by identifying and correcting discrepancies.

Best Practices for Implementing Inventory Control Systems

To effectively implement inventory control systems, businesses should consider the following best practices:

- Establish clear inventory control policies and procedures.

- Regularly review and update inventory control systems to ensure their effectiveness.

- Use technology to automate inventory management tasks and improve accuracy.

- Train staff on inventory control techniques and best practices.

- Monitor inventory levels closely and make adjustments as needed.

By implementing these best practices, businesses can effectively manage their inventory levels, optimize their operations, and maximize profitability.

Inventory Optimization

Inventory optimization is the process of determining the optimal level of inventory to hold in order to meet customer demand while minimizing costs. Inventory optimization can help businesses improve their cash flow, reduce their risk of stockouts, and increase their overall profitability.There are a number of different strategies that can be used to optimize inventory levels.

Some of the most common strategies include:

- Just-in-time (JIT) inventory: JIT inventory is a system in which businesses only order inventory when they need it. This can help businesses reduce their carrying costs and improve their cash flow.

- Safety stock: Safety stock is a buffer of inventory that businesses hold in order to protect themselves from stockouts. Safety stock can help businesses avoid lost sales and maintain customer satisfaction.

- Economic order quantity (EOQ): EOQ is a formula that businesses can use to determine the optimal quantity of inventory to order each time they place an order. EOQ can help businesses minimize their total inventory costs.

Inventory optimization can have a significant impact on business performance. Businesses that are able to optimize their inventory levels can improve their cash flow, reduce their risk of stockouts, and increase their overall profitability.

Examples of Inventory Optimization

Here are a few examples of how inventory optimization can improve business performance:

- A manufacturing company was able to reduce its inventory levels by 20% by implementing a JIT inventory system. This helped the company improve its cash flow and reduce its carrying costs.

- A retail store was able to reduce its stockouts by 50% by implementing a safety stock system. This helped the store increase its sales and improve customer satisfaction.

- A wholesale distributor was able to reduce its total inventory costs by 10% by using an EOQ formula to determine the optimal quantity of inventory to order each time it placed an order.

These are just a few examples of how inventory optimization can improve business performance. By implementing the right inventory optimization strategies, businesses can improve their cash flow, reduce their risk of stockouts, and increase their overall profitability.

Inventory Management in Different Industries

Inventory management practices vary across industries due to unique product characteristics, demand patterns, and supply chain dynamics. Understanding these differences is crucial for effective inventory management.

Specific industries pose unique challenges and considerations:

Manufacturing

- Complex supply chains with multiple components and raw materials

- Need for safety stock to prevent production disruptions

- Just-in-time (JIT) inventory management to reduce holding costs

Retail

- High inventory turnover rates

- Seasonal demand fluctuations

- Focus on optimizing stock levels to meet customer demand

Healthcare

- Critical importance of inventory accuracy for patient safety

- Strict regulations and compliance requirements

- Perishable inventory and short shelf lives

Case Studies

Nike: Manufacturing

Nike implements a demand-driven inventory system that leverages real-time sales data to adjust production levels, minimizing excess inventory and optimizing stock availability.

Walmart: Retail

Walmart’s cross-docking strategy reduces inventory holding costs by eliminating the need for storage. Goods are directly shipped from suppliers to distribution centers and then to stores, ensuring high inventory turnover.

Pfizer: Healthcare

Pfizer uses radio-frequency identification (RFID) technology to track inventory and prevent counterfeiting. This ensures accurate and timely delivery of critical medical supplies.

Technology in Inventory Management: Business Inventories Y Ae

Technology plays a crucial role in modern inventory management, enabling businesses to optimize their inventory levels, improve accuracy, and enhance efficiency. It has revolutionized the way businesses track, manage, and control their inventory.

There are various types of inventory management software available, each designed to meet the specific needs of different businesses. These software solutions offer a range of features, including:

- Real-time inventory tracking

- Automated inventory replenishment

- Inventory optimization algorithms

- Integration with other business systems

Technology can significantly improve inventory accuracy by eliminating manual errors and providing real-time visibility into inventory levels. This enables businesses to make informed decisions about inventory replenishment and avoid overstocking or stockouts.

Moreover, technology can enhance inventory efficiency by automating tasks such as inventory counting, order processing, and shipping. This frees up employees to focus on other value-added activities, such as customer service or product development.

Benefits of Inventory Management Software, Business inventories y ae

- Improved inventory accuracy

- Reduced inventory costs

- Increased sales and customer satisfaction

- Improved efficiency and productivity

- Enhanced decision-making

Ending Remarks

In conclusion, business inventories Y AE are a cornerstone of supply chain management, impacting various aspects of business operations. By embracing effective inventory management practices, businesses can optimize inventory levels, reduce costs, enhance customer satisfaction, and gain a competitive edge.

This guide has provided a comprehensive overview of the key concepts, methods, and techniques involved in inventory management. By implementing these strategies, businesses can unlock the full potential of their inventory, driving growth and profitability.

Essential Questionnaire

What are the different types of business inventories?

Business inventories are classified into various types, including raw materials, work-in-progress, finished goods, and maintenance, repair, and operating supplies.

How does inventory valuation impact financial statements?

Inventory valuation methods, such as FIFO, LIFO, and weighted average cost, affect the value of inventory reported on financial statements, impacting profitability and tax liability.

What are the key benefits of inventory control techniques?

Inventory control techniques help businesses minimize inventory levels, reduce waste, improve accuracy, and optimize cash flow.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY