Business chemical inventory management is a critical aspect of operations, ensuring the efficient and compliant handling of hazardous and valuable substances. This comprehensive guide explores the challenges, best practices, and strategies for maintaining an accurate and optimized chemical inventory.

From understanding regulatory requirements to implementing effective tracking systems, we delve into the intricacies of business chemical inventory management to empower businesses with the knowledge and tools to excel.

Business Chemical Inventory Management

Maintaining an accurate and efficient chemical inventory is crucial for businesses that utilize chemicals in their operations. It ensures compliance with regulations, optimizes resource allocation, and enhances overall safety.

Managing a large and diverse chemical inventory presents challenges, including:

- Tracking multiple chemical types and their properties

- Ensuring accurate record-keeping for regulatory compliance

- Preventing hazardous chemical interactions and accidents

Best Practices for Chemical Inventory Management

To effectively manage a chemical inventory, businesses should adopt best practices such as:

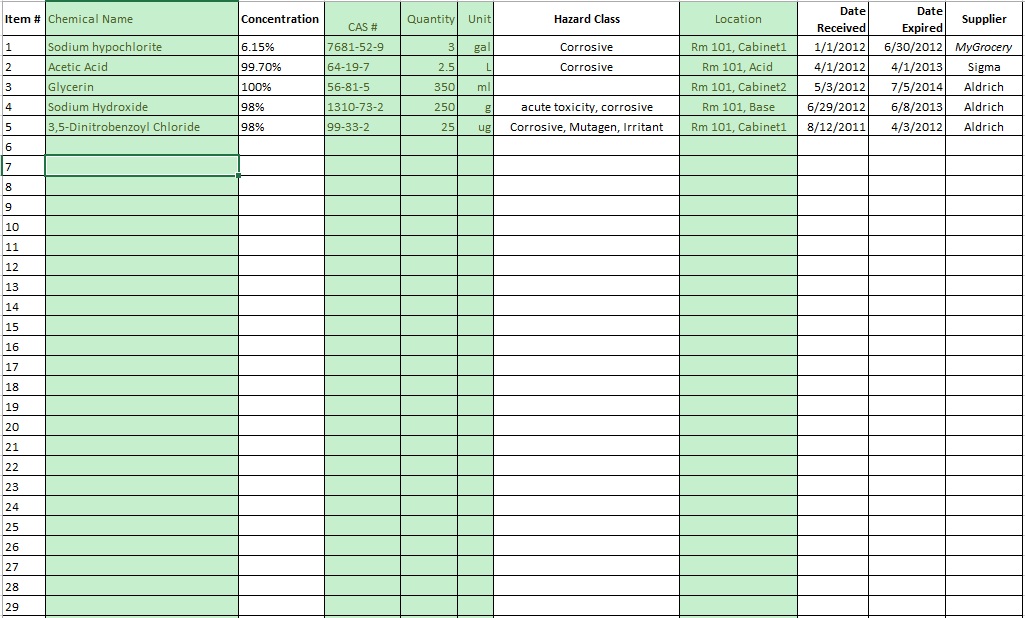

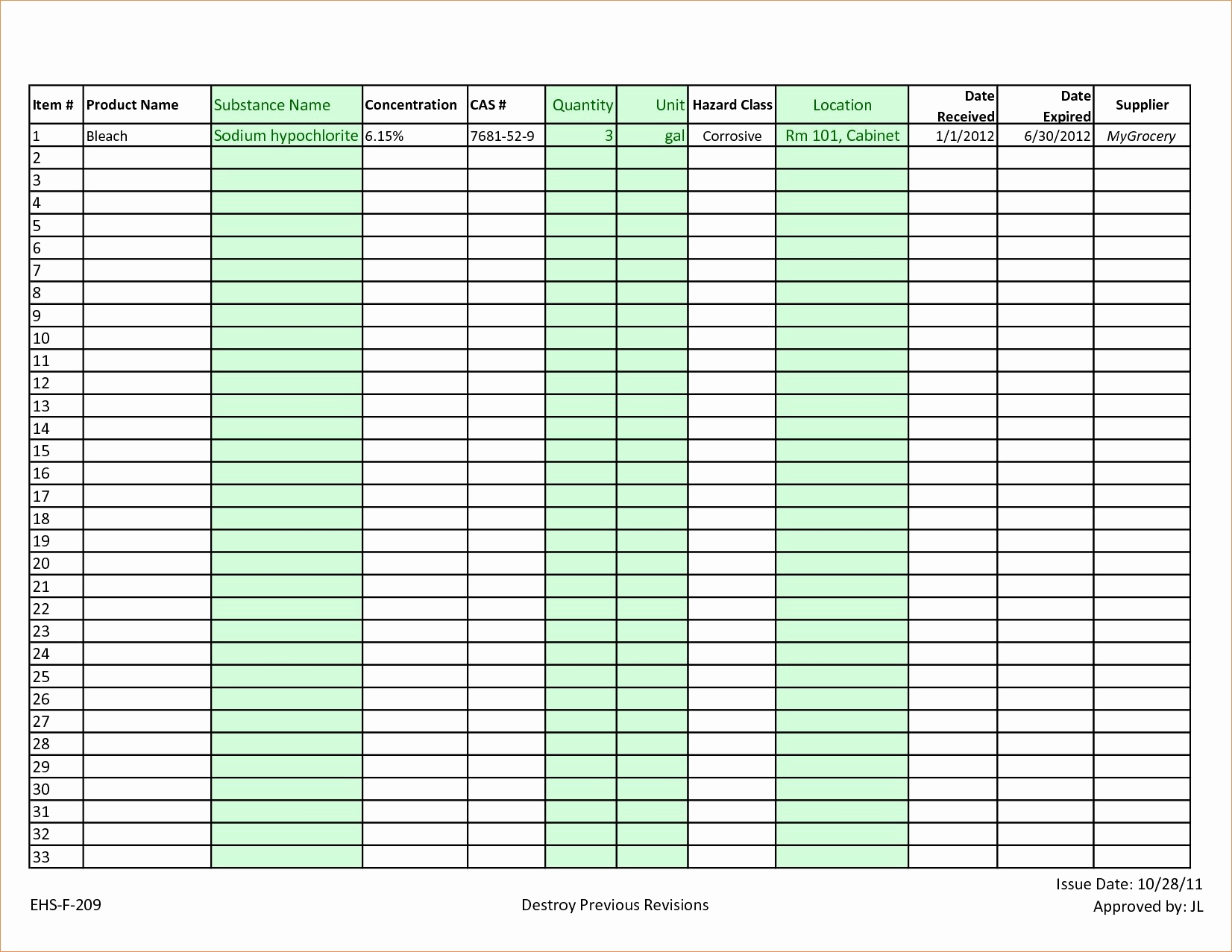

- Centralized Database:Establish a comprehensive database that tracks all chemical inventory information, including quantities, locations, and safety data sheets (SDSs).

- Regular Audits:Conduct periodic audits to verify inventory accuracy, identify discrepancies, and ensure compliance with regulations.

- Employee Training:Provide thorough training to employees on chemical handling, storage, and disposal procedures to prevent accidents and ensure proper inventory management.

- Hazard Communication:Implement a hazard communication program that effectively conveys chemical hazards and safety precautions to employees.

- Technology Integration:Utilize software or mobile applications to streamline inventory management, track chemical movements, and generate reports.

Chemical Inventory Tracking Systems

Chemical inventory tracking systems are essential for businesses that use or store chemicals. These systems help businesses to track the quantity, location, and movement of chemicals, as well as to manage the associated risks.

There are a variety of chemical inventory tracking systems available, each with its own advantages and disadvantages. The best system for a particular business will depend on the size and complexity of the business, the types of chemicals used, and the regulatory requirements that apply.

Types of Chemical Inventory Tracking Systems

- Manual systemsare the simplest and least expensive type of chemical inventory tracking system. They typically involve using spreadsheets or paper records to track chemical inventory.

- Automated systemsuse software to track chemical inventory. Automated systems can be more expensive than manual systems, but they offer a number of advantages, such as improved accuracy, reduced labor costs, and enhanced regulatory compliance.

- Cloud-based systemsare a type of automated system that is hosted on the internet. Cloud-based systems offer a number of advantages, such as scalability, flexibility, and ease of use.

Advantages and Disadvantages of Chemical Inventory Tracking Systems

| Type of System | Advantages | Disadvantages |

|---|---|---|

| Manual systems | – Inexpensive

|

– Inaccurate

|

| Automated systems | – Accurate

|

– Expensive

|

| Cloud-based systems | – Scalable

|

– Can be expensive

|

Selecting the Right Chemical Inventory Tracking System, Business chemical inventory

When selecting a chemical inventory tracking system, businesses should consider the following factors:

- The size and complexity of the business

- The types of chemicals used

- The regulatory requirements that apply

- The budget

- The IT resources available

Businesses should also consider the long-term costs of the system, including the cost of maintenance and upgrades. It is important to select a system that is scalable and can meet the future needs of the business.

Chemical Inventory Compliance

Chemical inventory compliance ensures that businesses adhere to regulatory requirements for managing hazardous chemicals, protecting the environment and human health. Non-compliance can lead to legal liabilities, fines, and reputational damage.

Regulatory requirements vary depending on the jurisdiction and the specific chemicals involved. Common requirements include:

- Maintaining accurate and up-to-date inventories of hazardous chemicals.

- Proper storage, handling, and disposal of chemicals.

- Regular inspections and audits to ensure compliance.

Consequences of Non-Compliance

Non-compliance with chemical inventory regulations can have serious consequences, including:

- Fines and penalties from regulatory agencies.

- Legal liability for environmental damage or harm to human health.

- Damage to the company’s reputation and loss of customer trust.

Strategies for Ensuring Compliance

Businesses can ensure chemical inventory compliance by implementing the following strategies:

- Establish a comprehensive chemical inventory management system that tracks all hazardous chemicals on-site.

- Train employees on proper chemical handling, storage, and disposal procedures.

- Conduct regular inspections and audits to identify and correct any compliance issues.

- Stay up-to-date on regulatory changes and best practices for chemical inventory management.

Chemical Inventory Optimization

Chemical inventory optimization is the process of managing chemical inventory levels to ensure that businesses have the right chemicals, in the right quantities, at the right time, and at the right cost. Optimizing chemical inventory can help businesses improve efficiency, reduce costs, and improve safety.

There are a number of different methods for optimizing chemical inventory. Some common methods include:

- Using inventory management software

- Implementing a just-in-time inventory system

- Using safety stock

- Conducting regular inventory audits

Businesses can also optimize their chemical inventory by working with suppliers to improve delivery times and reduce costs.

Benefits of Optimizing Chemical Inventory

There are a number of benefits to optimizing chemical inventory, including:

- Improved efficiency

- Reduced costs

- Improved safety

- Increased customer satisfaction

Examples of Chemical Inventory Optimization

There are a number of examples of businesses that have successfully optimized their chemical inventory. One example is a chemical manufacturing company that implemented a just-in-time inventory system. This system allowed the company to reduce its inventory levels by 50% while still meeting customer demand.

Another example is a pharmaceutical company that used inventory management software to improve its inventory accuracy by 95%. This improvement in accuracy helped the company to reduce its inventory costs by 10%.

Chemical Inventory Reporting: Business Chemical Inventory

Chemical inventory reporting is a crucial aspect of chemical inventory management that involves generating various reports to provide information about the chemical substances and their quantities within a business. These reports are essential for ensuring compliance with regulatory requirements, optimizing inventory levels, and maintaining safety.

To generate accurate and timely chemical inventory reports, businesses should follow best practices such as establishing clear reporting procedures, using reliable data sources, and implementing automated reporting systems. Effective chemical inventory reporting formats include tabular reports that provide detailed information about each chemical, including its name, CAS number, quantity, storage location, and safety hazards.

Types of Chemical Inventory Reports

Various types of chemical inventory reports are required for different purposes. Some common types include:

- Material Safety Data Sheets (MSDSs): These reports provide detailed information about the chemical’s physical and chemical properties, health hazards, and emergency response procedures.

- Tier II Reports: These reports are required under the Emergency Planning and Community Right-to-Know Act (EPCRA) and provide information about the presence of hazardous chemicals above certain threshold quantities.

- Inventory Reconciliation Reports: These reports compare the physical inventory with the records to identify any discrepancies and ensure accuracy.

- Usage and Consumption Reports: These reports track the usage and consumption of chemicals over time, helping businesses identify trends and optimize inventory levels.

- Waste Generation Reports: These reports track the generation of chemical waste and provide information for proper disposal and compliance with environmental regulations.

Closing Summary

By embracing the principles and practices Artikeld in this guide, businesses can transform their chemical inventory management into a competitive advantage. Enhanced safety, reduced costs, and improved compliance are just a few of the rewards that await those who master the art of business chemical inventory management.

FAQ Summary

What are the key challenges in managing a chemical inventory?

Managing a large and diverse chemical inventory presents challenges such as ensuring accuracy, maintaining compliance, and mitigating risks associated with hazardous substances.

How can businesses optimize their chemical inventory?

Businesses can optimize their chemical inventory by implementing just-in-time inventory systems, conducting regular audits, and leveraging technology for tracking and forecasting.

What are the consequences of non-compliance with chemical inventory regulations?

Non-compliance with chemical inventory regulations can result in fines, legal penalties, reputational damage, and potential harm to employees and the environment.

wohnroom.biz.id BUSINESS INVENTORY

wohnroom.biz.id BUSINESS INVENTORY